Falling Film Evaporator – Industrial Scale

Falling Film Evaporator Introduction

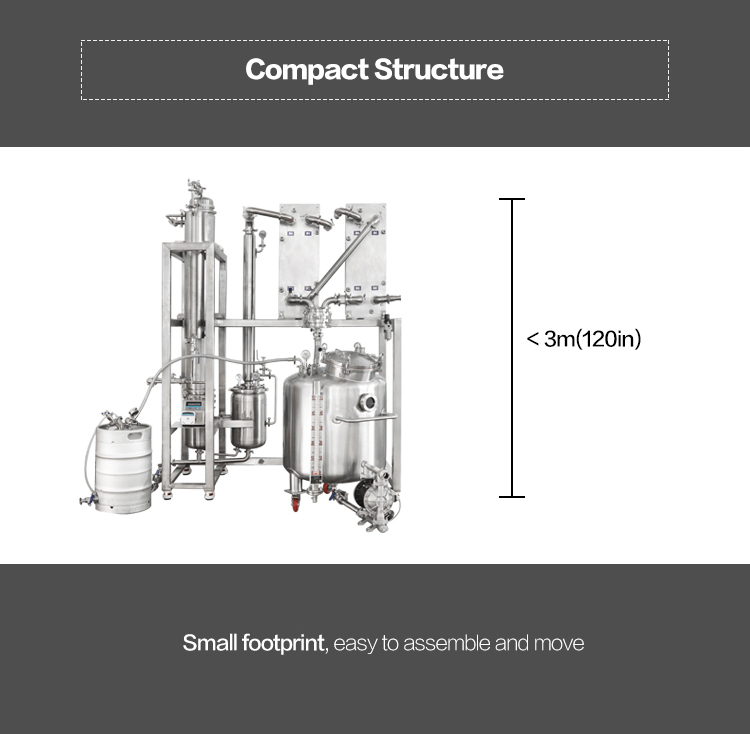

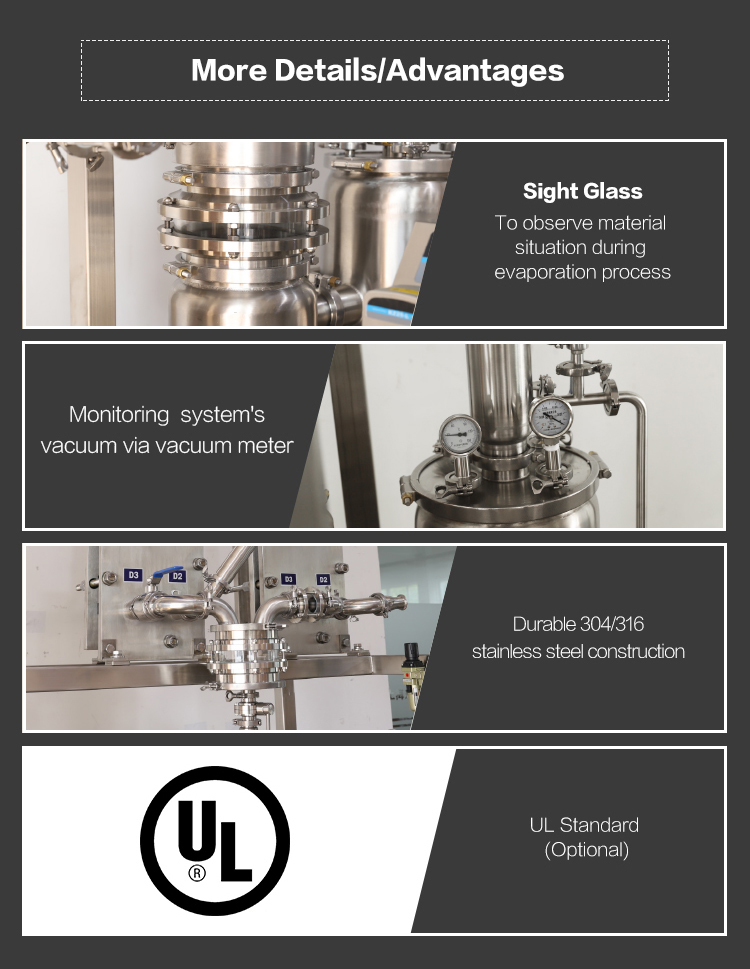

Our Scientific is offering a turnkey solution for industrial-scale falling film evaporator with 100L/hr-1000L/hr evaporation rate, capable of distilling more than 100L/hr crude oil. With the compact design, our falling film evaporator is easy to assemble and to move.

Our offers the whole solution for herbs extraction and crude oil distillation.

-

100L/hr – 1000L/hr evaporation rate available.

-

Short residence time.

-

Compact structure, small footprint.

-

Easy to assemble and move.

Technical Parameters of Falling Film Evaporator

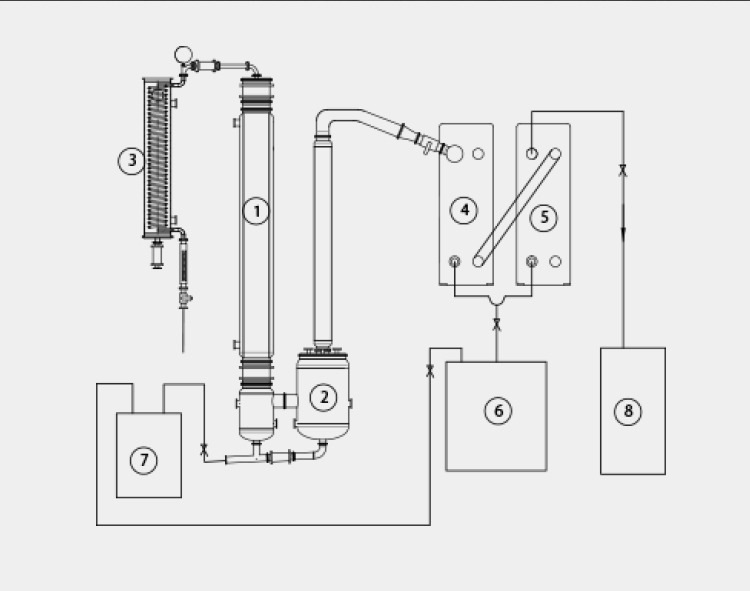

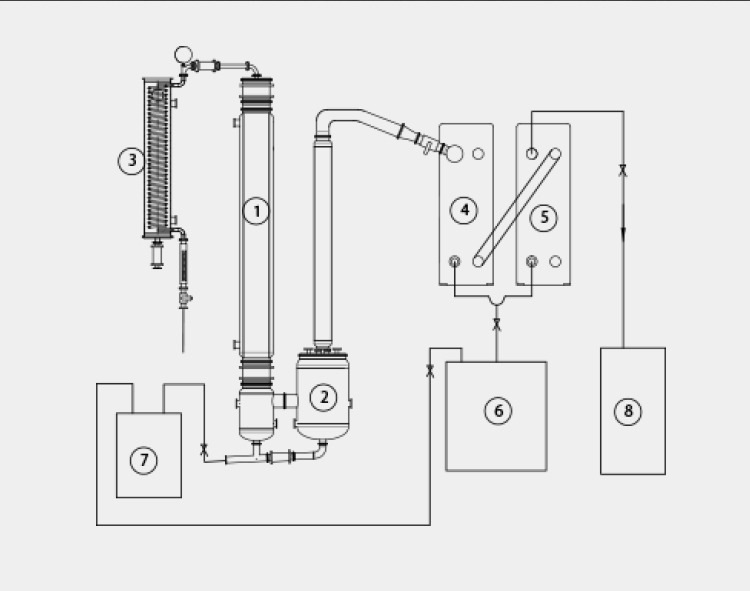

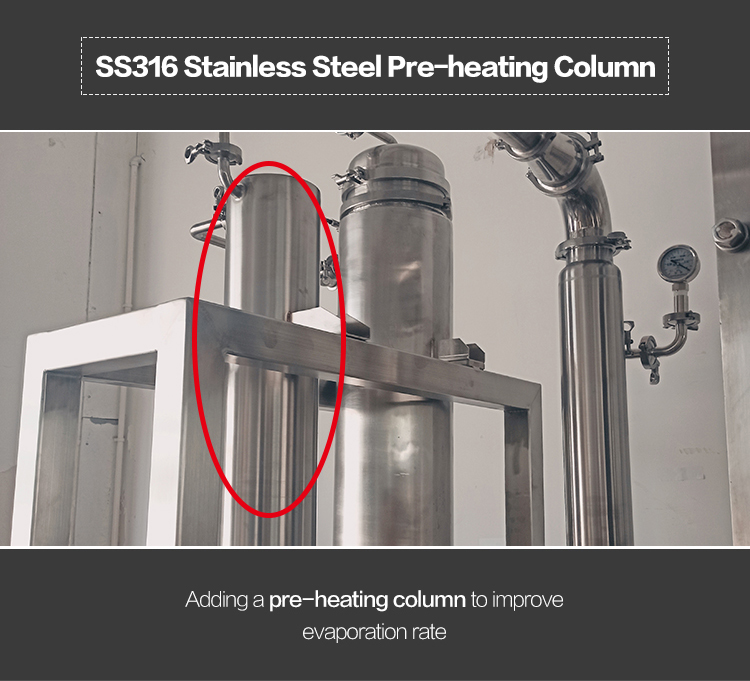

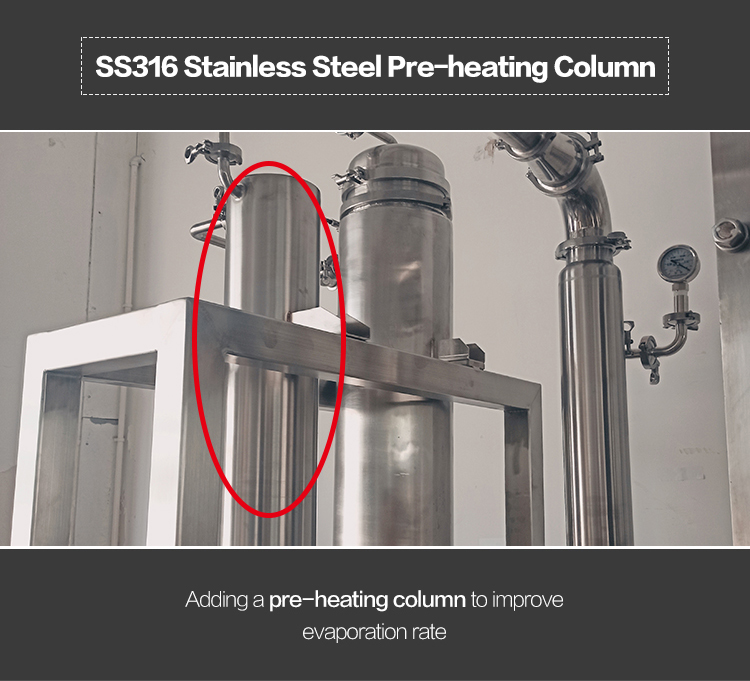

| ①Shell-and-tube heat exchanger | ③Preheater | ⑤Plate heat exchanger 2 | ⑦Storage tank 2 |

| ②Oil-air separator | ④Plate heat exchanger | ⑥Storage tank 1 | ⑧Vacuum pump |

Technical Parameters

| Model | FFE-100L | FFE-200L | FFE-30OL | FFE-500L |

| Ethanol throughput (Lh) | 100 | 200 | 300 | 500 |

| Solvent recovery efficiency | 98%-99.99% | |||

| Ethanol recovery efficiency | 98%-99.99% | |||

| Material | SUS316L(material contact part);suS304(other parts) | |||

| Heavier component tank (L) | 60 | 60 | 120 | 120 |

| Ethanol recovery tank(L) | 120 | 250 or 120 | 250 | 250 |

| Discharging interface | 1.5” | |||

| Feoding interface | 3/4″ | |||

| Vacuum interface | 3″ | 3″ | 3″ | 3″ |

| Dimension(mm) | 1350×800 x2420 | 1800 x900x2420 | 1900x950x2430 | 2200×1000 x2940 |

| Weight (kg) | 750 | 9o0 | 1000 | 1150 |

| Voltage | System voltage is based on the suppoting circulators(no electricity for itself) | |||

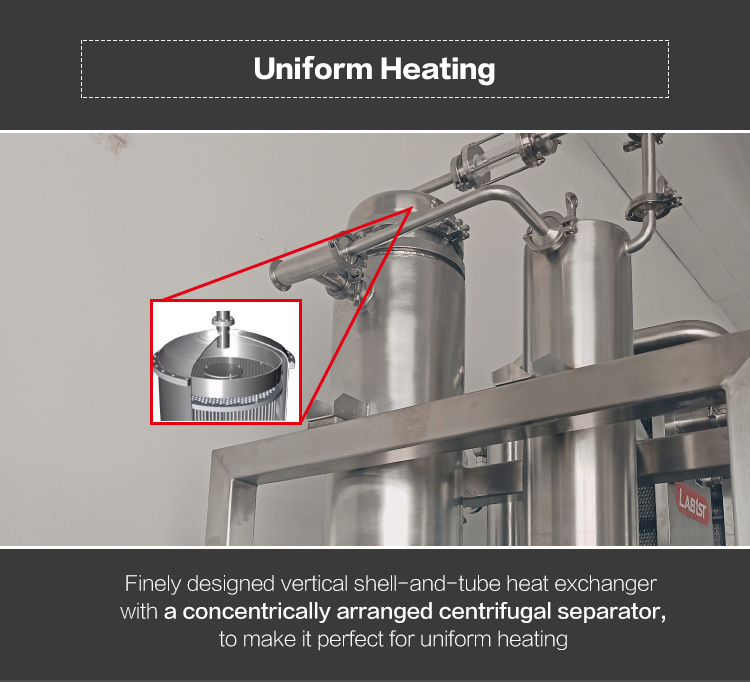

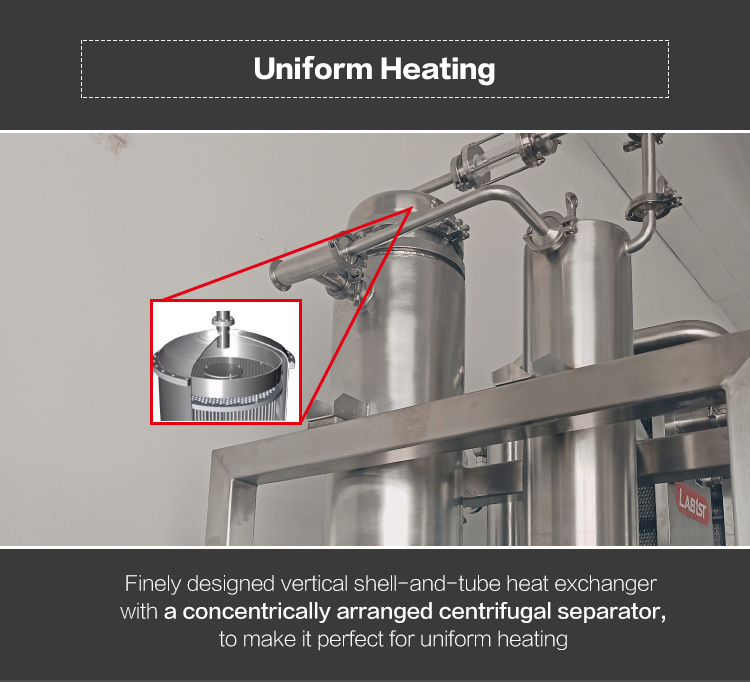

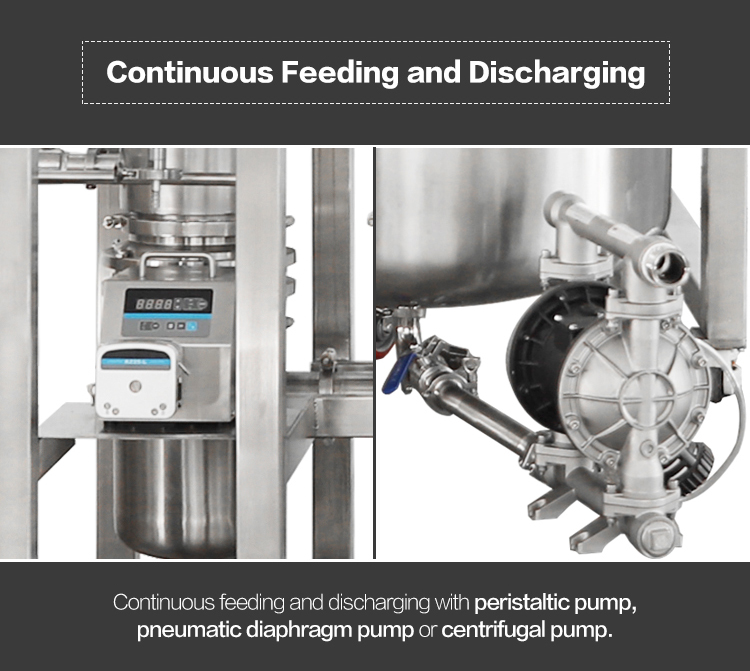

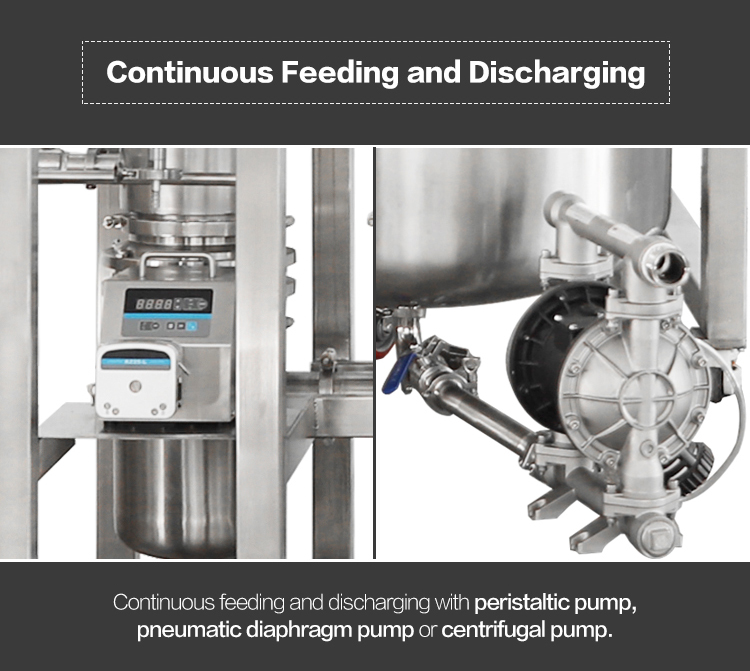

Show Details of Falling Film Evaporator

Turnkey Solution of Falling Film Evaporator:

CONTACT US

Send us your enquiries and our representative will answer you accordingly.