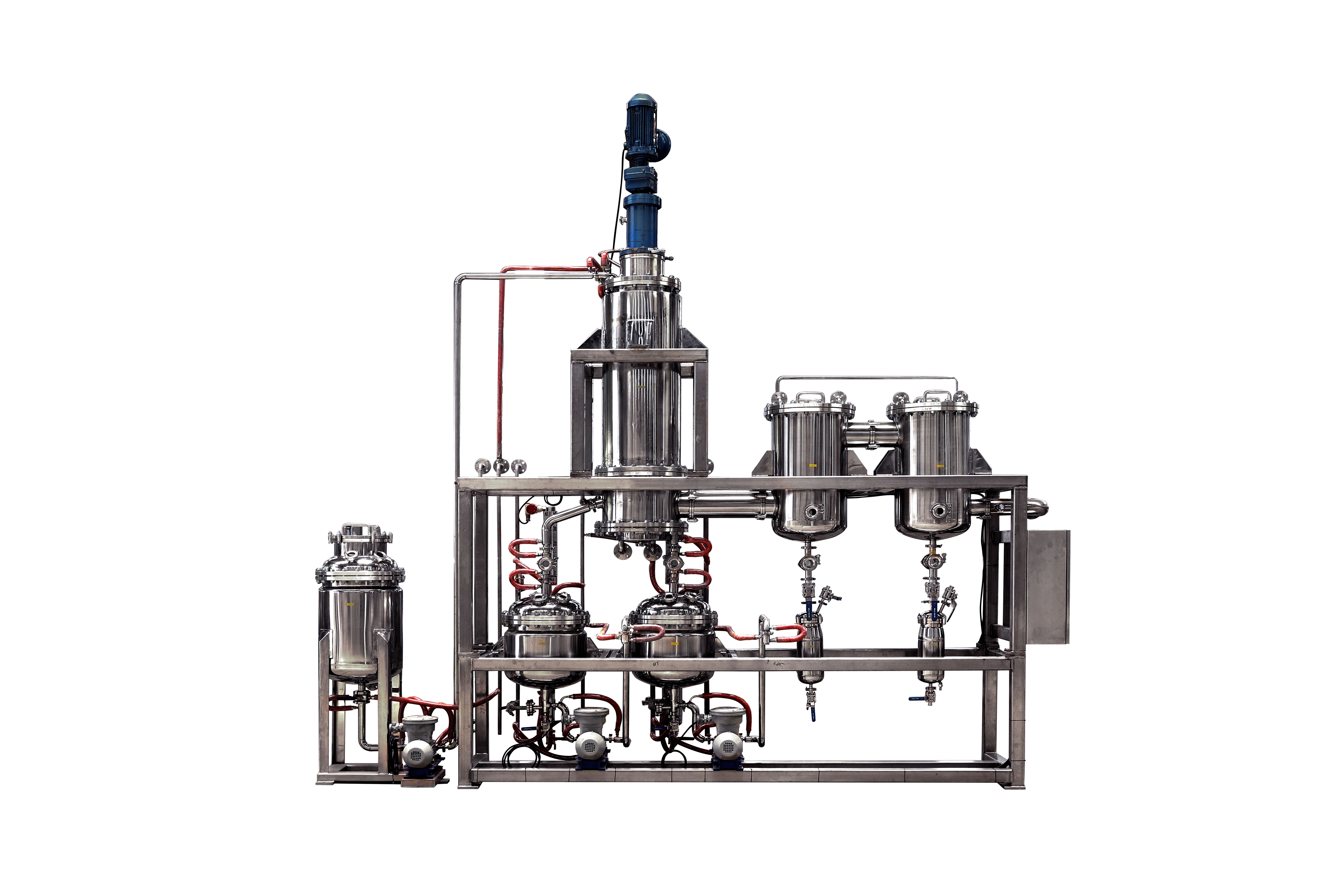

Falling Film Evaporator – Industrial Scale

Industrial Wiped Film Distillation System Introduction

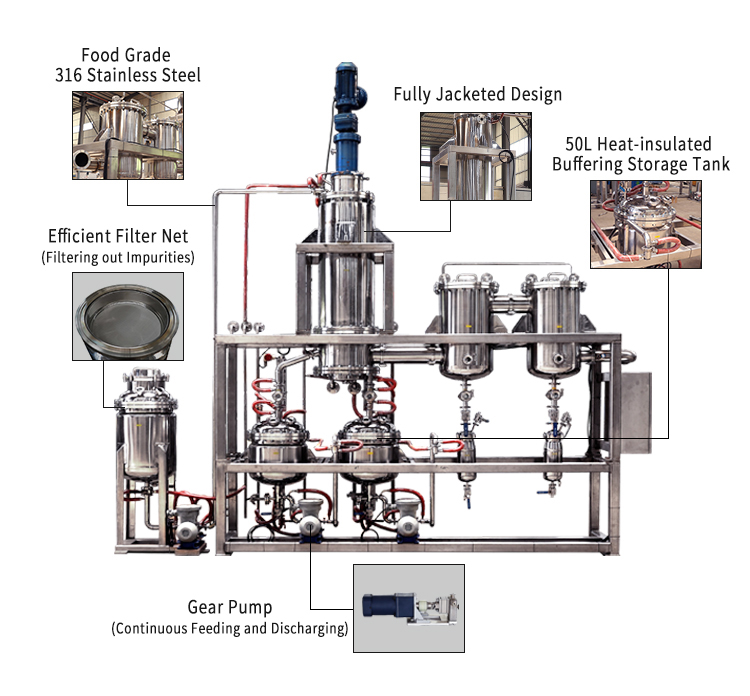

Our Scientific is offering a turnkey solution for industrial-scale wiped film (molecular) distillation systems with 1m², 2m², 3m², or larger evaporation surface area, capable of distilling more than 100L/hr crude oil.

The standard one stage wiped film (molecular) distillation system can be customized to multi-stages according to customer’s requirements.

-

Larger throughput, up to 200kg/hr.

-

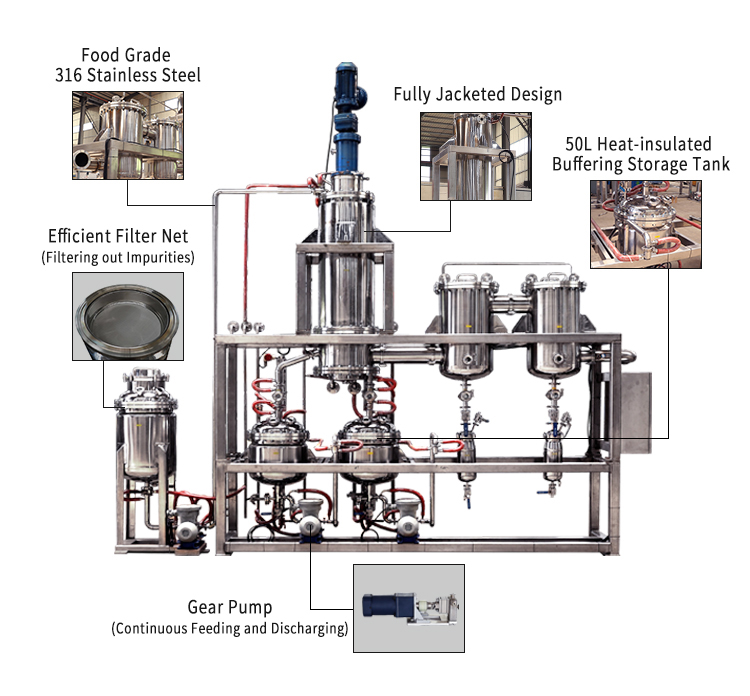

SS316L design, durable in use.

-

Short residence time and uniform heating

-

Automatic and continuous distillation process.

Technical Parameters

| Evaporator | Part No. | SMD-10 | SMD-20 | SMD-50 |

| Evaporation Area | 1 ㎡ | 2 ㎡ | 5 ㎡ | |

| Material | 316L | |||

| Power | 1.5KW | 3KW | 4KW | |

| Variable Frequency Drive | Constant Speed | |||

| Seal | Mechanical Seal | |||

| Wiper Style | Scraper | |||

| Feed Vessel | Volume | 100L | 100L | 200L |

| Type | Jacketed | |||

| Material Inlet | Method | Gear Pump | ||

| Processing Rate | 20L~60L/H | 30L~100L/H | 50L~300L/H | |

| Power | 750W Variable Frequency Drive | |||

| ColdTrap | Dewar Style (1pcs ) | 3㎡ | 3㎡ | 10㎡ |

| Cooling Coil (1pcs) | 3㎡ | 3㎡ | 10㎡ | |

| Receiving Vessel (2pcs) | 5L | 5L | 5L | |

| Distillate & Residue | Processing Rate | 20L ~ 60L/H | 30L ~ 100L/H | 50L ~ 200L/H |

| Storage Tank | 50L Heat insulated Buffering Storage Tank | |||

| Method | Gear Pump | |||

| Power | 750W | 750W | 1.5KW | |

| Variable Frequency Drive | ||||

| Internal Condenser Temperature Control | Water Tank Volume | – | 100L | 200L |

| Heating Power | 6KW | 6KW | ||

| Heat Exchanging Area | 5㎡ | 10㎡ | ||

| Pipeline | Jacketed | |||

| Support Frame | 304 Stainless Steel Pipe | |||

| Integrated Electric Cabinet | Not explosion proof | |||

Turnkey Solution

CONTACT US

Send us your enquiries and our representative will answer you accordingly.