3.According to the distillation method of raw materials

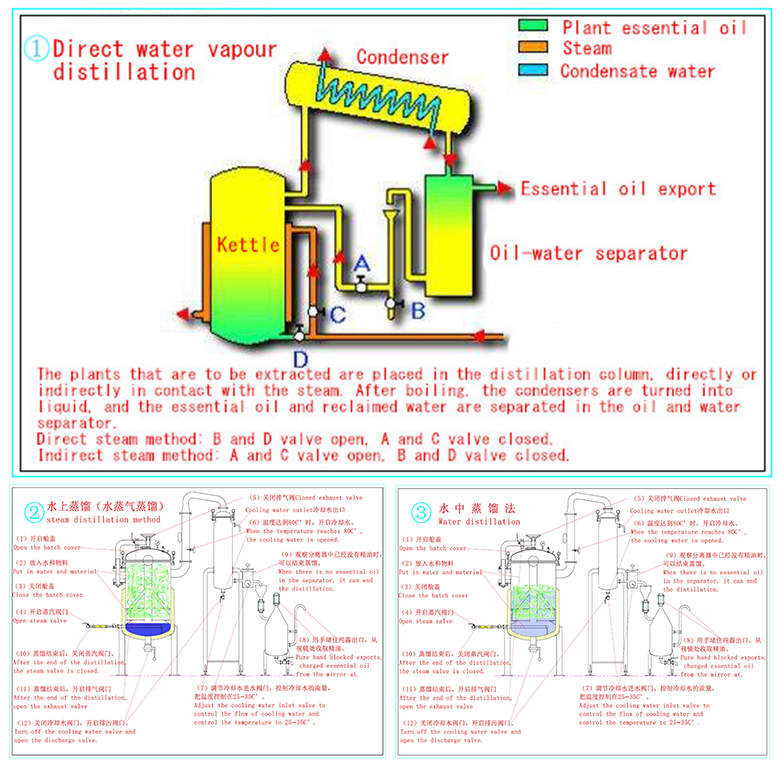

Different raw material distillation methods will also be different, the distillation tank of the equipment will also have great differences according to the distillation method, see the structure diagram.

Essential oil distillation methods can be divided into the following types:

1)Direct water vapor distillation

Direct water vapor distillation is a method of direct heating or distilling or distilling crude powders or fragments containing volatile components after soaking and wetting. such as Orange peel

2) steam distillation method

steam distillation is a method in which raw materials and water are placed in still pots and separated by a sieve plate. The steam heating mode is used. This method is widely used. It is applicable to small diameter, dry materials after crushing, and materials that are difficult to be adhered after being heated. such as

Lavender, chamomile, mint, lemongrass, eucalyptus leaves, white orchid, orange leaves, laurel leaves

3) Water distillation

Water distillation is a mode in which raw materials and water are put into a distillation pot according to a certain ratio, and raw materials and water are mixed and heated. This method is suitable for large, fragile, such as rose, and easily bonded raw materials. (Aromatic plants with high ester content are not recommended. Use this method)

4.According to the residual amount of essential oil materials and slag discharge method

The amount of raw material remaining in the essential oil distillation equipment will vary depending on the raw material and the distillation method.

The residue discharge of raw materials is mainly divided into the following types:

1)Butterfly valve slagging (manual, electric, pneumatic)

2)Large diameter pneumatic valve slagging

3)Side manhole slag

4)Basket slag discharge

5.We can customize the essential oil distillation equipment according to the customer’s special requirements and other requirements.