Macerated oils are also referred to as infused oils. They are created when carrier oils are used as solvents to extract therapeutic properties from plant material. The benefit of a macerated oil above a distilled oil is that more of a plant’s essence is captured in the oil, because it captures heavier, larger plant molecules than the ones captured in the distillation process. This keeps the product closer to retaining more of the plant’s valuable offerings.

The ideal plant material to be infused will be harvested so that it is as dry as possible, as any plant moisture will cause the oil to become rancid and will encourage microbial growth. Adding 5% of Vitamin E oil or Wheatgerm oil (which is high in Vitamin E) will prevent rancidity.

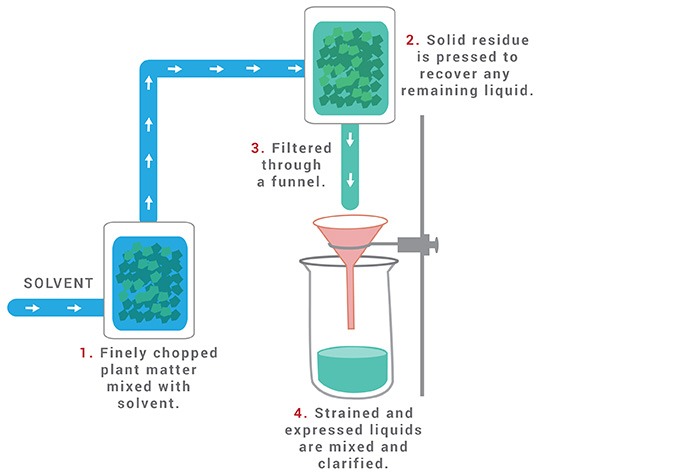

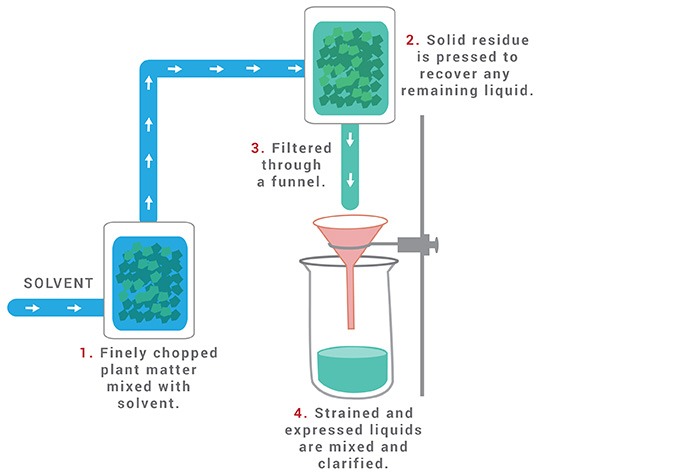

MACERATION PROCESS

- Plant material is finely cut, crushed, or ground into moderately coarse powder.

- Plant material is placed in a closed vessel.

- Solvent (Menstruum) is added.

- The mixture is allowed to stand for 1 week and is shaken occasionally.

- The liquid is strained.

- Solid residue (Marc) is pressed to recover any remaining liquid.

- Strained and expressed liquids are mixed.

- Liquids are clarified through filtration or subsidence.

When the maceration process is complete, the base oil will likely have changed color. The final maceration should be filtered of its plant material and poured into an airtight container to be stored in a cool, dry place for up to 12 months. A macerated oil will go cloudy or will smell bad when rancid.

5-10% of a macerated oil can be used as an ‘active botanical’ in a cosmetic formula. Used in a larger quantity, it can also replace a plain base oil.