Essential oils are natural in their most concentrated form. They are extracted directly from biomass (the bark, flowers, fruit, leaves, nut, resin, or roots of a plant or tree) and just one drop contains a complex network of molecules that deliver different effects to the body. Burning aromatic plant materials for incense has been a religious tradition throughout recorded history and, as far as we can tell, these practices ushered in the dawn of aromatherapy.

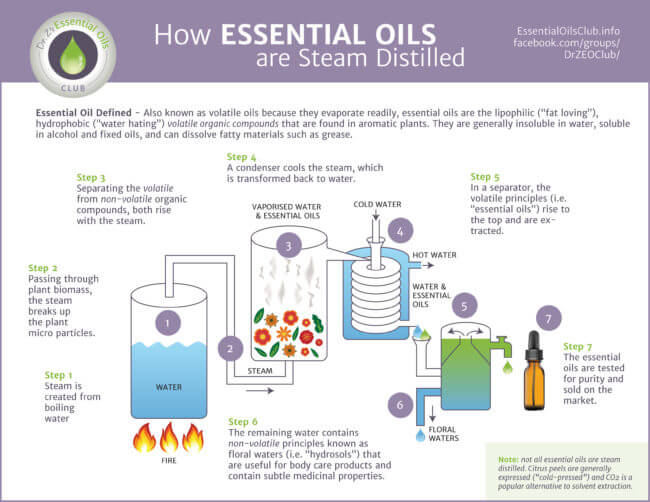

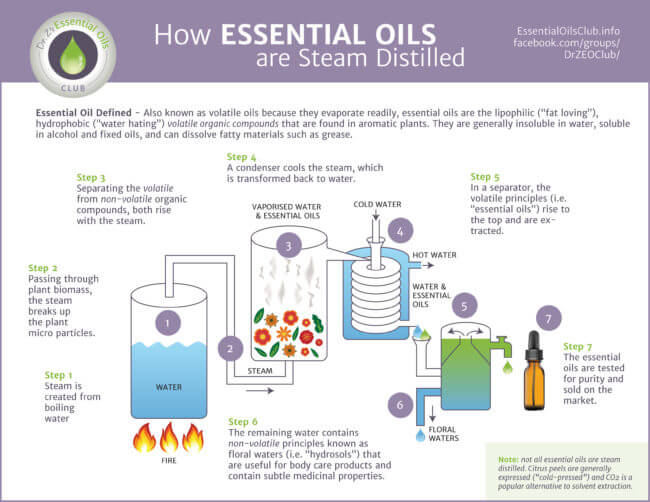

Also known as volatile oils because they evaporate readily, essential oils are lipophilic (“fat loving”), hydrophobic (“water-hating”) volatile organic compounds that are found in aromatic plants. Meaning, they have the tendency to dissolve or combine with fats or lipids, while repelling or not mixing with water. Somewhat of a misnomer, essential oils aren’t “oily” like the fixed, culinary oils we just discussed and they usually do not leave a residue when applied on your skin. They are generally insoluble in water, soluble in alcohol and fixed oils, and can dissolve fatty materials such as grease.

HOW ESSENTIAL OILS ARE MADE

Note, not all essential oils are steam distilled. Citrus peels are generally expressed (“cold-pressed”). Other aromatics include CO2 extracts and absolutes. Here’s a quick breakdown of the most common extraction methods.

- CO2 Extraction – Supercritical fluid extraction (SFE) uses supercritical carbon dioxide (sCO2), which is a fluid state where CO2 is held at or above its critical temperature and critical pressure. In its supercritical, fluid state, it has an uncanny ability to perform as a commercial and industrial solvent. Unlike other commonly used toxic solvents, like hexane, CO2 is safe and environmentally friendly. The resulting essential oil-based extract is currently all the rage in the aromatherapy community.

- Distillation – Primarily accomplished with steam, essential oils can also be water-and-steam distilled as well as steam-vacuum distilled. The end products are hydrosols (“floral waters”) and essential oils.

- Expression – Primarily reserved for citrus peels, mechanical pressing (aka “cold pressing”) literally squeezes the essential oils out of the rind of a fruit. At one point in history, this was done by hand using a sponge to collect the oil, but those days are long gone. Citrus oils can also be steam distilled, but the aroma has a tendency to change considerably and the therapeutic properties are much different.

- Solvent extraction – A type of liquid-to-liquid extraction, this is what our Biblical ancestors utilized to extract minuscule amounts of frankincense essential oil out of the resin by placing it in olive oil for a short time. Today, it is used for delicate, low-essential oil-content flowers like rose, jasmine, mimosa, and others. The process has been expedited and much more of the essential oil can be extracted by using petroleum ether or chemical solvents like ethanol and hexane; all of which have safety concerns for us and for the environment. For this reason, safer alternatives like CO2 extraction are becoming more popular. Solvent extraction produces a waxy, fatty substance known as concrete. When the concrete is washed with alcohol, the fat is separated and the remaining end product contains volatile and non-volatile principles referred to as an absolute.

HOW TO DISTILL ESSENTIAL OILS

HOW TO DISTILL ESSENTIAL OILS: THE 7 BASIC STEPS TO STEAM DISTILLATION:

- Step 1 – Steam is created from boiling water

- Step 2 – Passing through plant biomass, the steam breaks up the plant micro particles.

- Step 3 – Separating the volatile from non-volatile organic compounds, both rise with the steam.

- Step 4 – A condenser cools the steam, which is transformed back to water.

- Step 5 – In a separator, the volatile principles (i.e. “essential oils”) rise to the top and are extracted.

- Step 6 – The remaining water contains non-volatile principles known as floral waters (i.e. “hydrosols”) that are useful for body care products and contain subtle medicinal properties.

- Step 7 – The essential oils are tested for purity and sold on the market.

1. Preparing bio-mass

- Break up plant matter (leaves, flowers, bark, etc.), but not so small that the biomass falls through netting at bottom of the flask.

2. Filling the water reservoir

- Fill flask about ½ – 2/3 way up

- Use funnel – helps

- Filtered / distilled water is best

3. Adding plant matter to 2 liter bio-mass flask

- Pack full using wooden dowel rod

4. Preloading receiver w/distilled water

- If you don’t, the EO will get lost into hydrosol

5. Reuse your hydrosols

- During for your next distillation, fill the water flask with hydrosols from previous distillations to extract even more essential oils! Be sure to store in the refrigerator to prevent bacterial overgrowth.

It takes about 30 minutes for things to start to kick in and the process will last around 3 hours.

1 Comment. Leave new

Would like to know, which of the above mentioned methods is used to extract garlic oil, at the same time keeping its characteristics.

Thank you