The essential oils we know are generally extracted from the leaves, flowers, seeds, fruits, roots, bark, resin, wood, etc. of plants by distillation, cold pressing, fat absorption or solvent extraction. In addition to extracting essential oils from a single area, some plants can extract essential oils in several areas. For example, bitter orange can extract essential oils from the three parts of the flower buds, leaves and fruits.

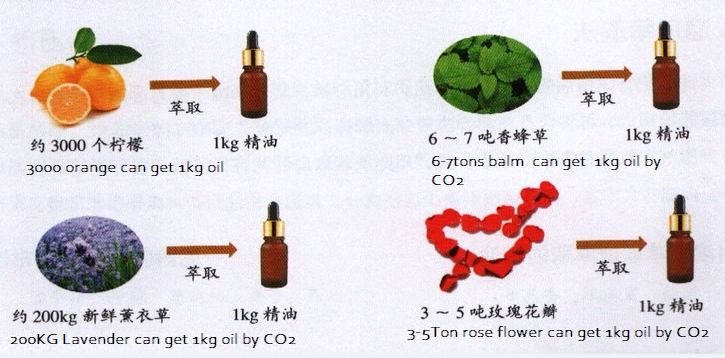

Distillation method:

The distillation method is the simplest and the cost is low. Currently, 95% of the essential oils on the market are extracted by distillation.

The method is to put fresh or dried aromatic plant raw materials (flowers, leaves, wood chips, etc.) into a rectifier, and send steam from below to evaporate the essential oil of the plant. The water vapor containing the essential oil is collected and cooled by the conduit, and then condensed into a liquid, which is separated by the difference in specific gravity and density of the water and the essential oil.

Distillation is often used to extract plants that are flowers, leaves, stems, and roots. During the cooling process, the circulating water can be used multiple times. In the remaining water, more or less some essential oils are dissolved inside. This is called soy water, which is pure dew.

Essential oils extracted by distillation:

Basil, carrot seed, chamomile, cinnamon, clary sage, alfalfa, cypress, eucalyptus, geranium, juniper, lavender, lemon balm, orange blossom, patchouli, peppermint, Bulgarian rose, rosemary, rosewood, sandalwood, tea tree, verbena, ylang-ylang

Extrusion method:

Water is added during the process of squeezing the peel, and after collecting the juice, the essential oil is separated by a centrifuge. Most citrus essential oils, such as grapefruit, lemon, and bergamot, are extracted by this method. Since most of the citrus essential oils are not resistant to the heat of distillation, such as the use of distillation, it will destroy its essence during the extraction process. Therefore, most of the essential oils of the peel are currently cold pressed by the machine.

Essential oils extracted by extrusion:

Bergamot, lemon, grapefruit, orange, red mandarin

Fat absorption method:

The lipid absorption method is the oldest method of extracting essential oils, called “lipid essence”. In general, petal oils are commonly used in this way. Put a piece of glass on the board, apply animal fat, and spread the petals. This layered the glass of the petals and placed them under the sun, using the heat of the sun to release the essence and immersing it in the grease. During the extraction process, the medicine often replaces the petals or flips the glass until the oil is saturated. Finally, it is treated with alcohol and stirred by a machine. After the alcohol evaporates, it leaves an aromatic oil.

This method is time-consuming and laborious. At present, apart from Grasse, France, it has almost disappeared from the general commercial market.

Essential oils extracted by lipid absorption:

Jasmine, orange blossom, rose

Solvent extraction method:

Solvent extraction

This is a common extraction method for floral essential oils. Using a solvent such as alcohol, ether or liquid butane, it is repeatedly drenched on the plant to be extracted, and then the solvent containing the essential oil is separated and analyzed, and the essential oil is obtained by low-temperature distillation.

Solvent extraction method is the latest extraction method. The floral essential oil extracted by this method contains complete and precious ingredients and has rich connotation. The distillation method lacks these ingredients. When purchasing essential oils, it can be used as a reference for comparison.

Essential oils extracted by solvent extraction:

Cinnamon, sage, benzoin,Cannabis

Carbon dioxide extraction method:

This extraction method began in 1980 and is a very expensive method with very complicated instruments and equipment. The carbon dioxide is pressurized to a semi-liquid semi-gas state, and the aromatic molecules of the plant are extracted, and the pressure is changed to volatilize the gas, and the remaining is the essential oil. The essential oil extracted by this method becomes “CO2 essential oil”.

The CO2 essential oil is of good quality and is said to be close to the state of the natural plant, and the aroma is perfect compared to the distillation method. However, due to the high price, CO2 essential oils are not very popular.

The production of essential oils is a process of race against time. Freshly picked fresh petals must enter the processing process within 12 hours, otherwise they will not be used!

Carbon dioxide extraction method:

Essential oil extraction

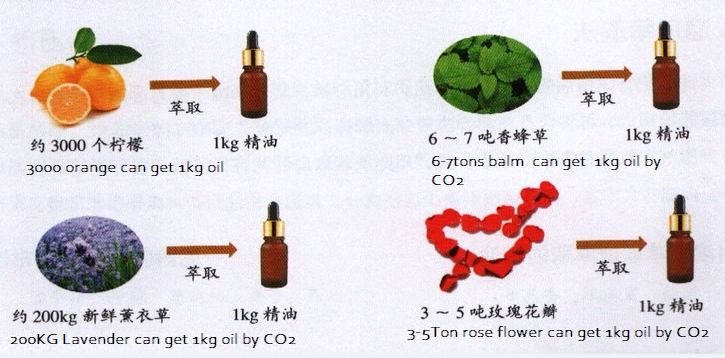

No matter which method you choose, you need a lot of plants to extract a small amount of essential oil, which is why the essential oil is so expensive. such as: