100L Essential Oil Distillation Equipment

Application of Essential oil Extraction Equipment

Our essential oil extraction equipment, health products, biological drugs, cosmetics, and food. This uses technology and chemical separation, can extract plant components efficiently by steam distillation, have a good effect in collecting essential oil from plants.

Main advantage of essential oil extraction equipment:

- By steam-distillation to reach the extraction of essential oils.

- Easy operation. One person can operate this machine easily.

- High efficiency. Using indirect heating of heat- transfer oil, it can quickly reach 100℃ high temperature under the conditions of cleanness, safety, and atmospheric pressure. If required, with a vacuum pump, the extraction speed of essential oils will be ore faster.

- Compact structure. It covers only about 1.5 square meters.

100L Essential oil Extraction Equipment Parameters

| Distillation kettle | Max volume 150L, effective volume 100L, material basket volume 80L, use jacket heating and steam direct heating, heat exchange area more 1m2. |

| Demister | Size Φ102×500, clamping band quick connect installation, demister to facilitate cleaning. Meet the GMP requirements. |

| Condensing tower |

Vertical condenser. Heat transfer area is greater than 2m2 . Pipeline: designed pressure: normal pressure;working pressure: normal Pressure; design temperature: 100℃, work temperature≤100℃. Working medium:Secondary steam. Length: Φ25×2; Shell: designed pressure: 0.3Mpa,working pressure: normal pressure; design temperature: 80℃,work temperature: 15~30℃. Working medium: cooling water. |

| Pure dew collection tank | 304 stainless steel production, volume 25L. |

| Electric steam boiler |

380v, 50Hz, adjustable 6-18kw, steam temperature: 120℃/100℃, steam production: 26kg/h, working pressure: 0.4 ~ 0.6MPa, cable cross-sectional area: 10㎡, water pressure: 0.4MPa. |

| Filter | 120 mesh filter, flow 2.0m³ / h, material for the S304。 |

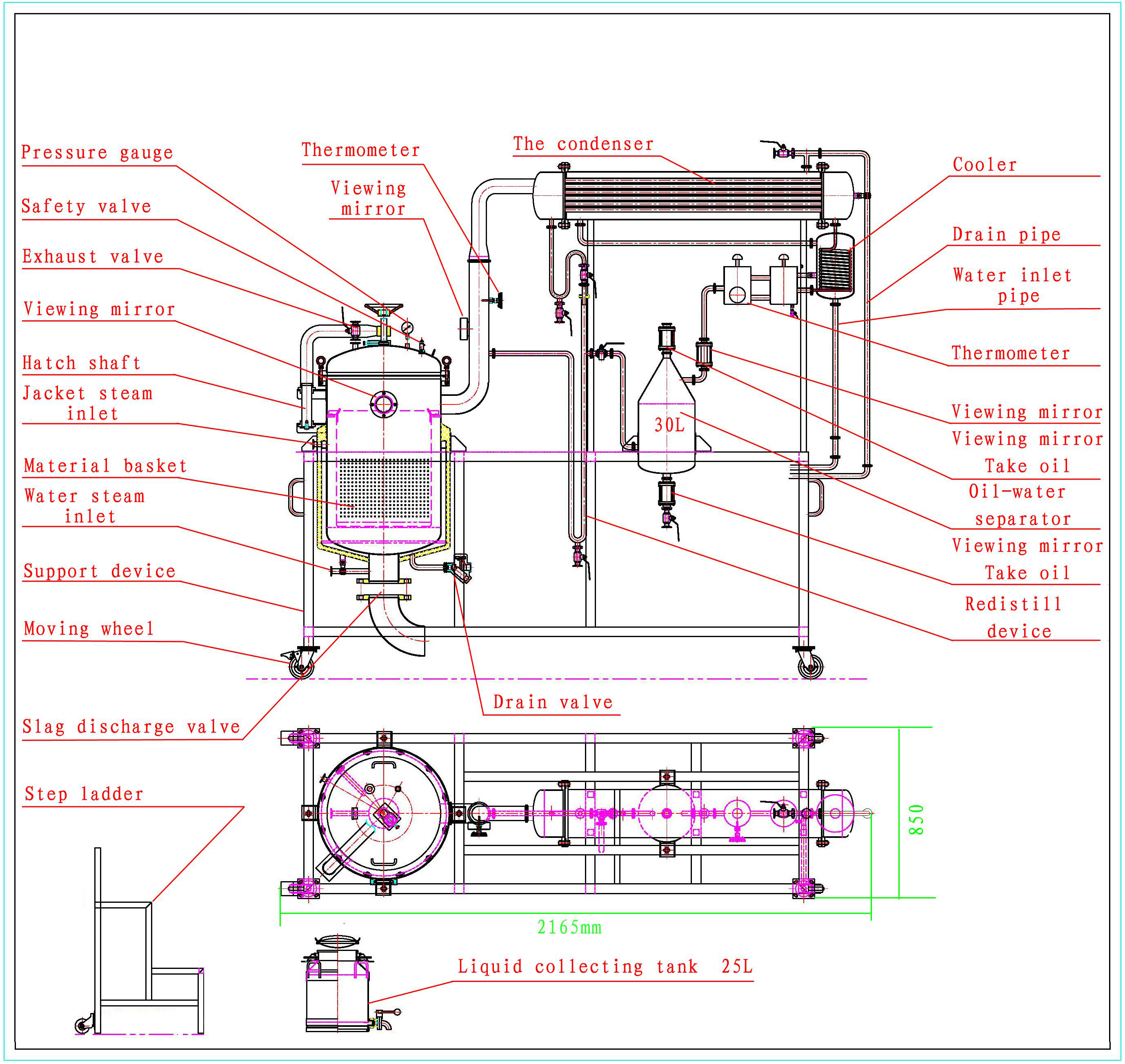

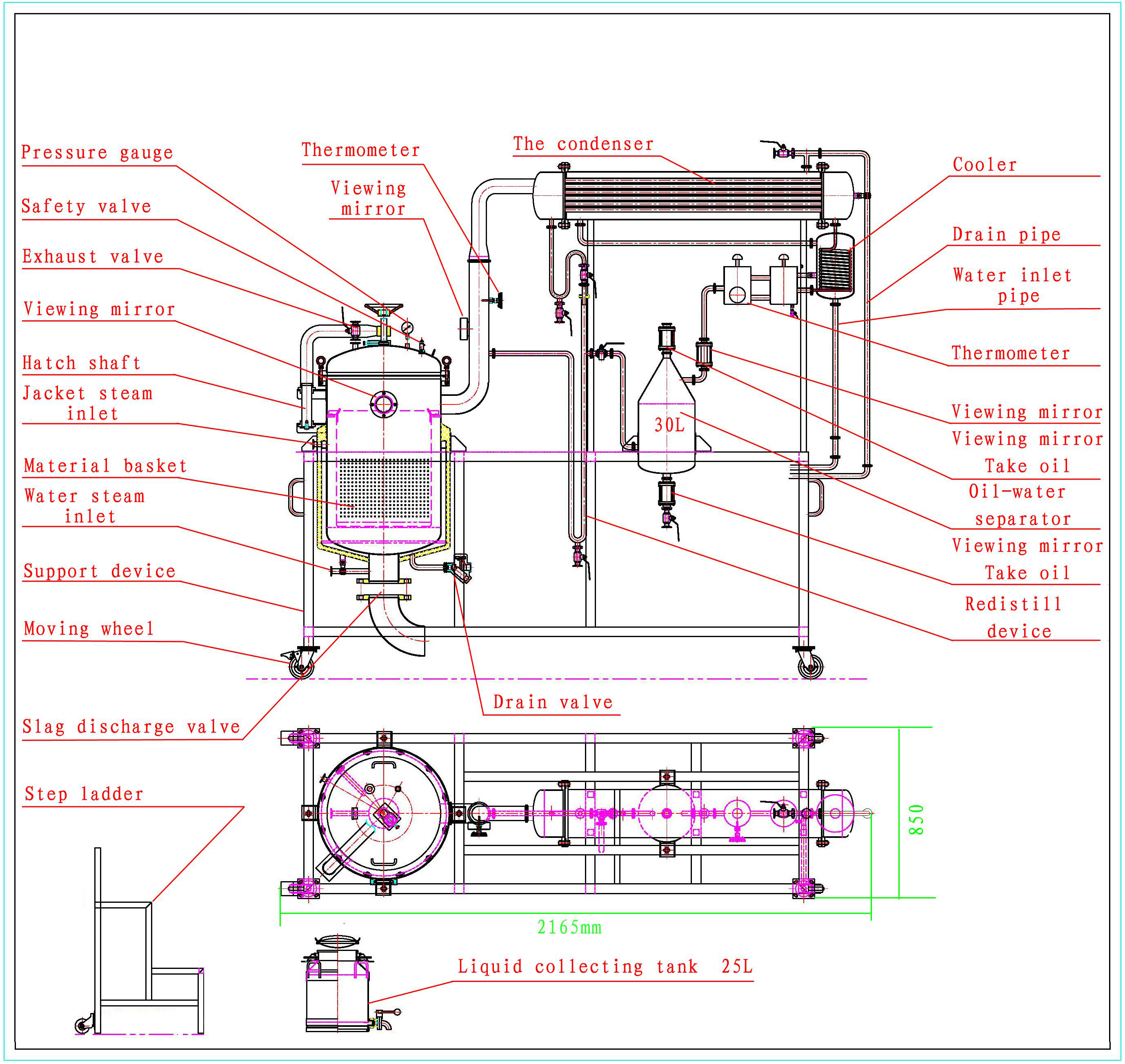

100L Essential oil Still Structure Diagram

The device consists of a distillation kettle, material basket, jacket heating layer, insulation layer, demister, condensing tower,re-distillation column, rectifier, oil-water separator, Electric steam boiler, filter, and other related pipeline composition.

- Distillation equipment is made of S304 stainless steel, equipment, surface polishing Ra ≤ 0.6μm, outer surface matte treatment Ra ≤ 0.8μm, to ensure that no health dead ends, meet GMP requirements.

- Include control box, manhole, cleaning ball, the water inlet, depending on the light mouth, sight glass, spare mouth, pressure gauge interface, thermometer interface, return port, outlet, through the steam mouth, and other related fittings.

100L Essential oil Distiller Common Spices

|

Description |

Raw material |

Description |

Raw material |

|

Gaultheria procumbens |

Gaultheria procumbens leaf |

Cinnamomum cassia |

Cinnamomum cassia |

|

Achillea millefolium |

Achillea millefolium Flowers and upper branches |

Santalum album |

Santalum album |

|

Cymbopogon nardus |

Cymbopogon nardus |

Matricaria chamomilla |

Matricaria chamomilla |

|

Pimenta dioica |

Pimenta dioica seeds |

Anthemis nobilis |

Anthemis nobilis flowers |

|

Angelica archengelica |

Angelica archengelica root |

Cinnamomum zeylanicum |

Cinnamomum zeylanicum Wood core and root core |

|

Angelica archengelica |

Angelica archengelica seeds |

Salvia sclarea |

Salvia sclarea Leaf |

|

Pimpinella anisum |

Pimpinella anisum seeds |

Eugenia caryophylatta |

Eugenia caryophylatta bud |

|

Arnica montana |

Arnica montana root |

Eugenia caryophylatta |

Eugenia caryophylatta Leaf |

Detail Show

CONTACT US

Send us your enquiries and our representative will answer you accordingly.