200L Essential oil Distillation Extraction Equipment

Advantages of Essential oil Distillation Extraction Equipment

- By steam-distillation to reach the extraction of essential oils.

- Easy operation. One person can operate this machine easily.

- High efficiency. Using indirect heating of heat- transfer oil, it can quickly reach 100℃ high temperature under the conditions of cleanness, safety, and atmospheric pressure. If required, with a vacuum pump, the extraction speed of essential oils will be ore faster.

- Compact structure. It covers only about 1.5 square meters.

200L Essential oil Distillation Extraction Equipment

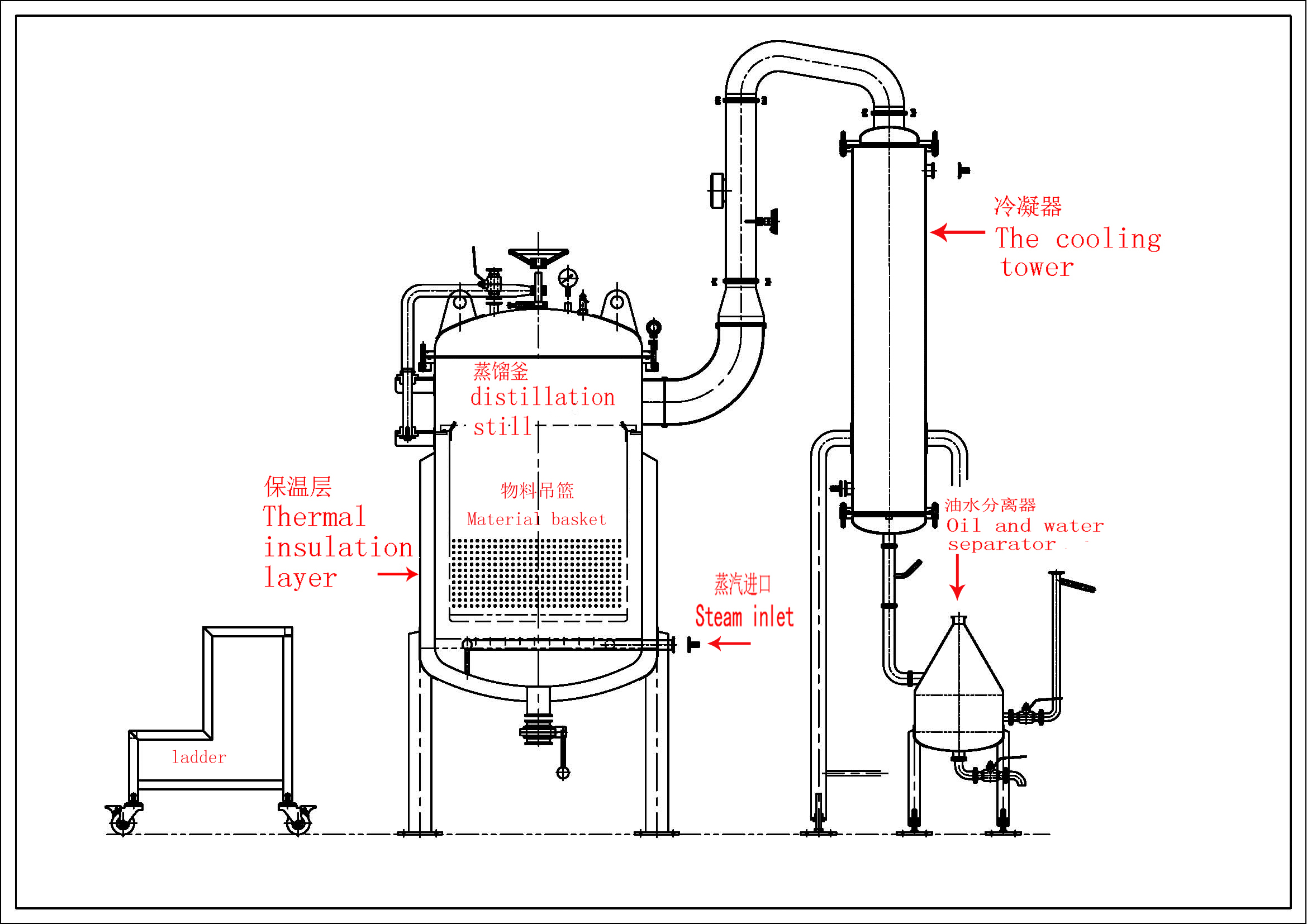

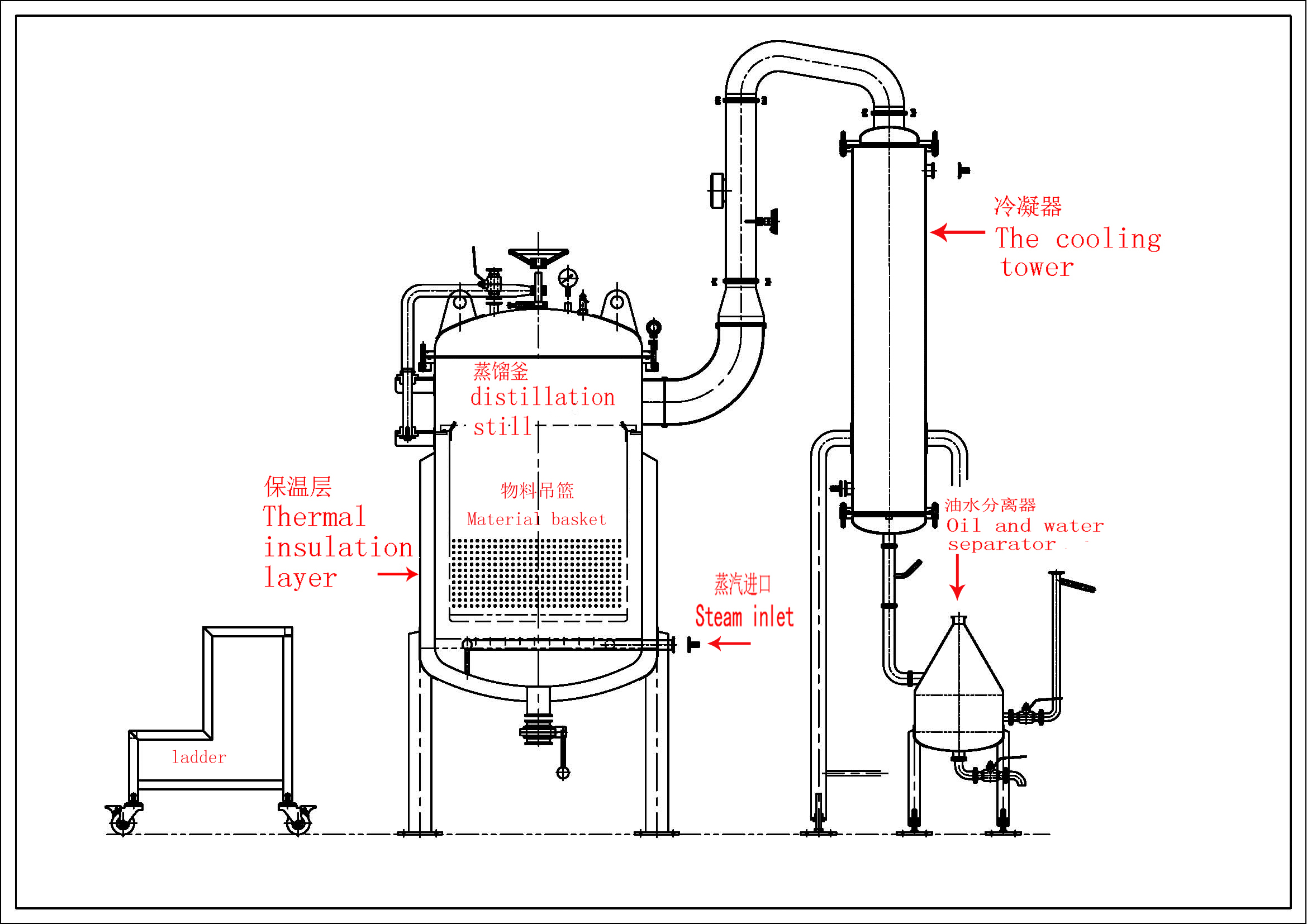

200L Essential oil Extraction Equipment Structure Diagram

The 200L essential oil extractor consists of a distillation kettle, material basket, insulation layer, demister, condensing tower, oil-water separator, (Gas or oil-fired boiler), and other related pipeline composition.

Technical Parameters

| Distillation still | Actual volume:200L Using steam through heating, heat transfer area of 5m². Kettle: Designed pressure 0.09Mpa. Working pressure:normal pressure Designed temperature:120℃.working temperature≤100℃ Working Medium: water |

| Demister | Demister: Size Φ102×400,clamping band quick connect installation, demister to facilitate cleaning.Meet the GMP requirements. |

| Condenser | Condensing tower: Vertical condenser, heat transfer area more than 2.5 m² Pipeline: designed pressure: normal pressure;working pressure: normal Pressure; design temperature: 100℃, work temperature≤100℃. Working medium:Secondary steam. Length: Φ25×2; Shell Pass: designed pressure: 0.3Mpa,working pressure: normal pressure; design temperature: 80℃,work temperature: 15~30℃. Working medium: cooling water. |

| Oil water separatorT | he special oil-water separator, stainless steel tank, glass as the cup, tank volume is 30L. |

| Duplex strainer | 20 mesh filter, flow 2.0m³ / h, material for the S30408. |

| Accessories | A thermometer, a pressure gauge, a mirror. |

| Electrical steam boiler | 24kw, 380v, tri-phase, 50Hz; |

| Note |

1, Distillation equipment are made of S304 stainless steel, equipment, surface polishing Ra ≤ 0.6μm, outer surface matte treatment Ra ≤ 0.8μm, to ensure that no health dead ends, meet GMP requirements. 2, Include pressure gauge interface, thermometer interface, through the steam port and other related fittings. |

Material Information

The material of Essential oil distillation extracting equipment:

|

Description |

Raw material |

Description |

Raw material |

|

Gaultheria procumbens |

Gaultheria procumbens leaf |

Cinnamomum cassia |

Cinnamomum cassia |

|

Achillea millefolium |

Achillea millefolium Flowers and upper branches |

Santalum album |

Santalum album |

|

Cymbopogon nardus |

Cymbopogon nardus |

Matricaria chamomilla |

Matricaria chamomilla |

|

Pimenta dioica |

Pimenta dioica seeds |

Anthemis nobilis |

Anthemis nobilis flowers |

|

Angelica archengelica |

Angelica archengelica root |

Cinnamomum zeylanicum |

Cinnamomum zeylanicum Wood core and root core |

|

Angelica archengelica |

Angelica archengelica seeds |

Salvia sclarea |

Salvia sclarea Leaf |

|

Pimpinella anisum |

Pimpinella anisum seeds |

Eugenia caryophylatta |

Eugenia caryophylatta bud |

|

Arnica montana |

Arnica montana root |

Eugenia caryophylatta |

Eugenia caryophylatta Leaf |

Products Show

CONTACT US

Send us your enquiries and our representative will answer you accordingly.