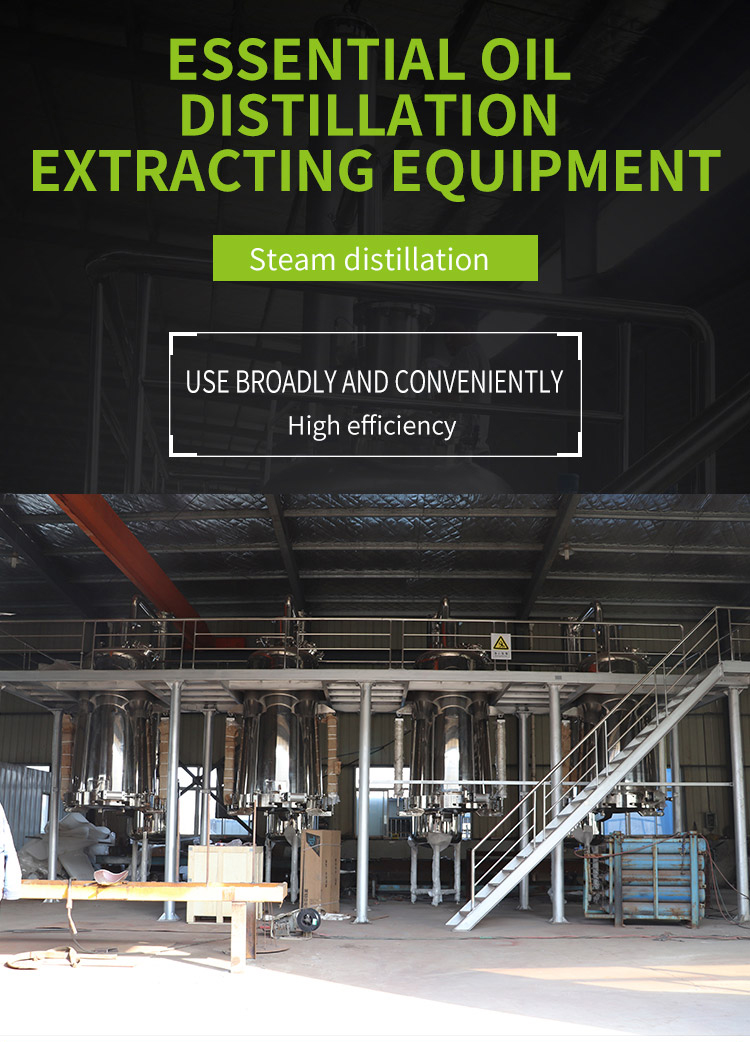

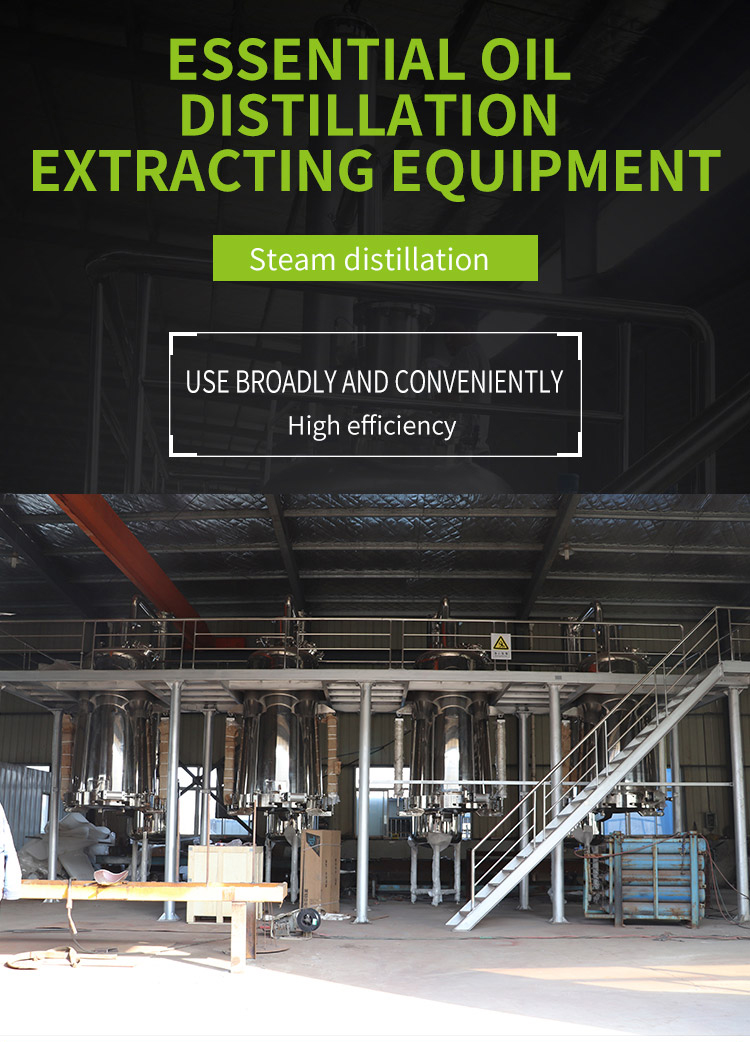

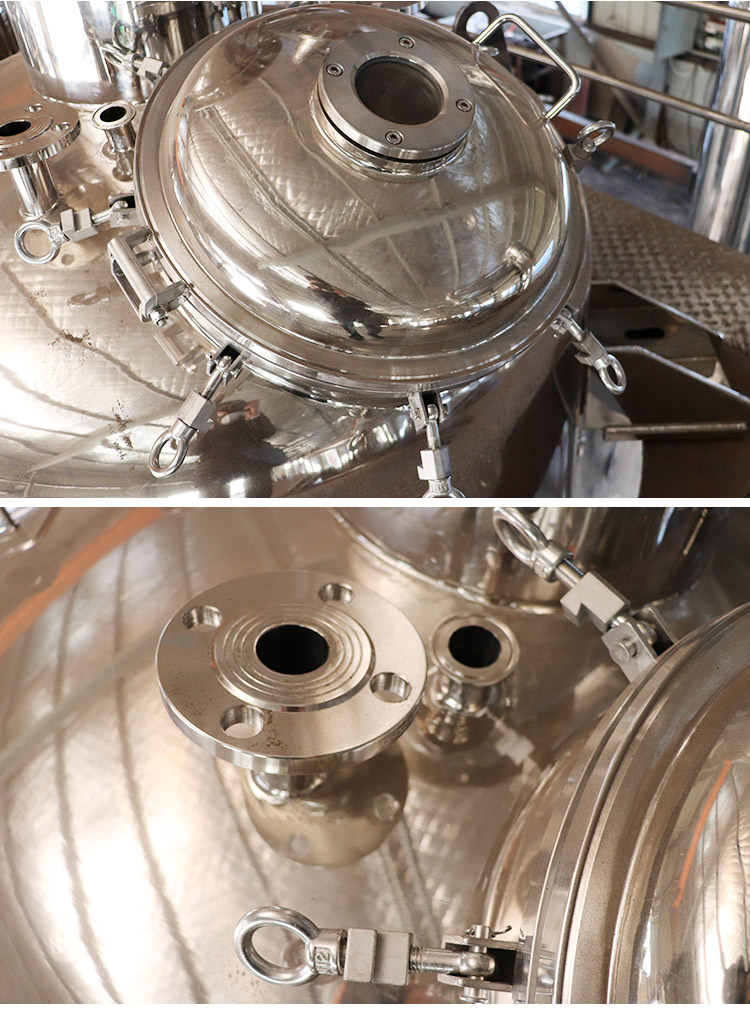

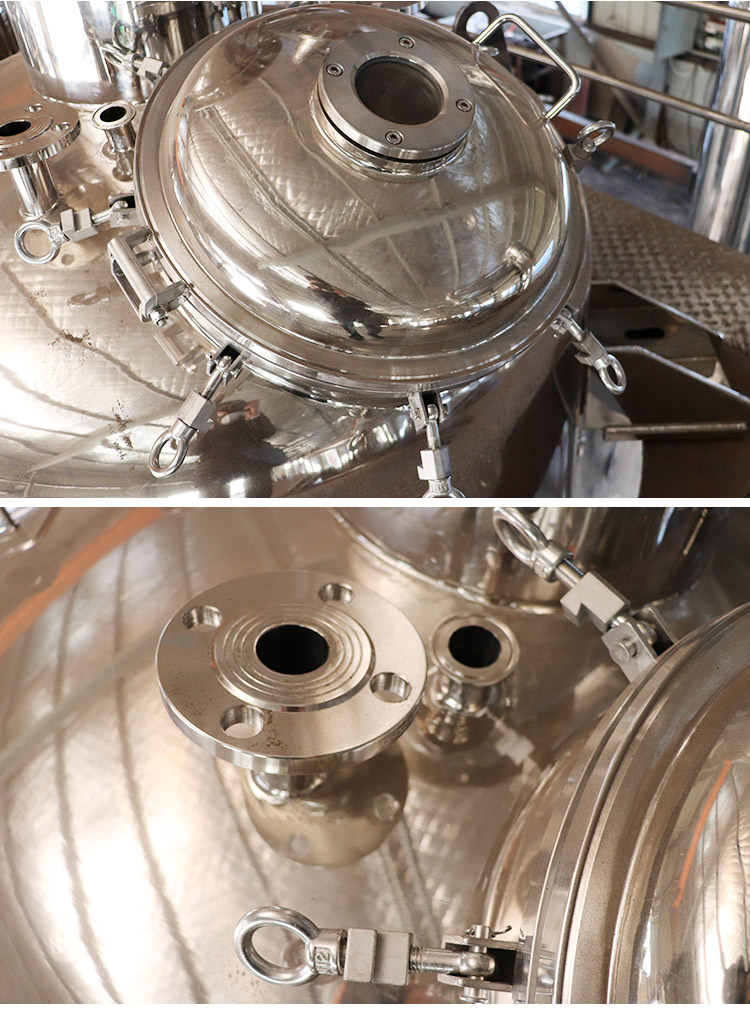

3000l Essential Oil Distillation Extraction Equipment

3000L Essential Oil Distillation Extraction Equipment Product Introduction

Essential oil steam distillation advanced and Continuously improving. We had specialized in essential oil extracting technology and equipment for more than 30 years, serviced thousands of customers all over the world. we hope to bring customers extraordinary experience and sincerely hope to serve you.

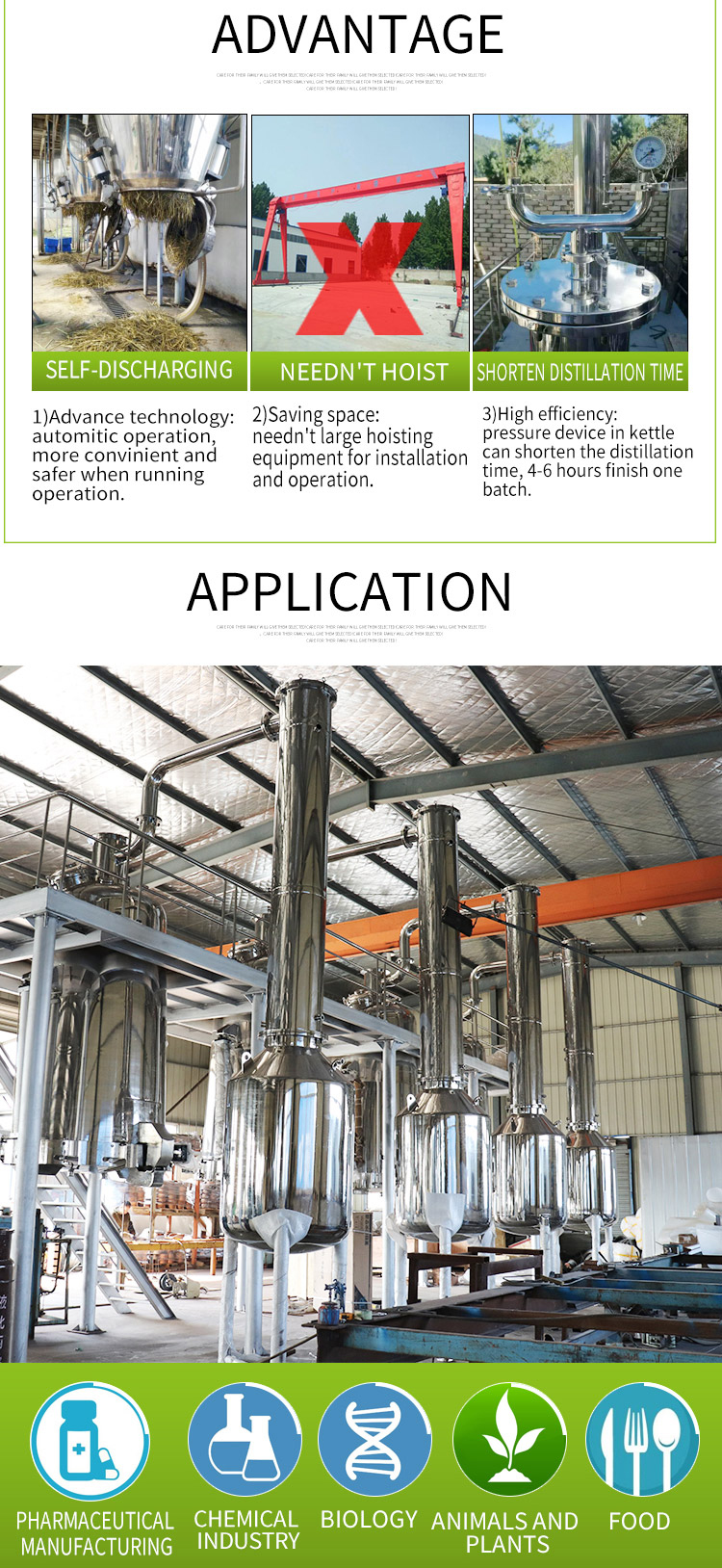

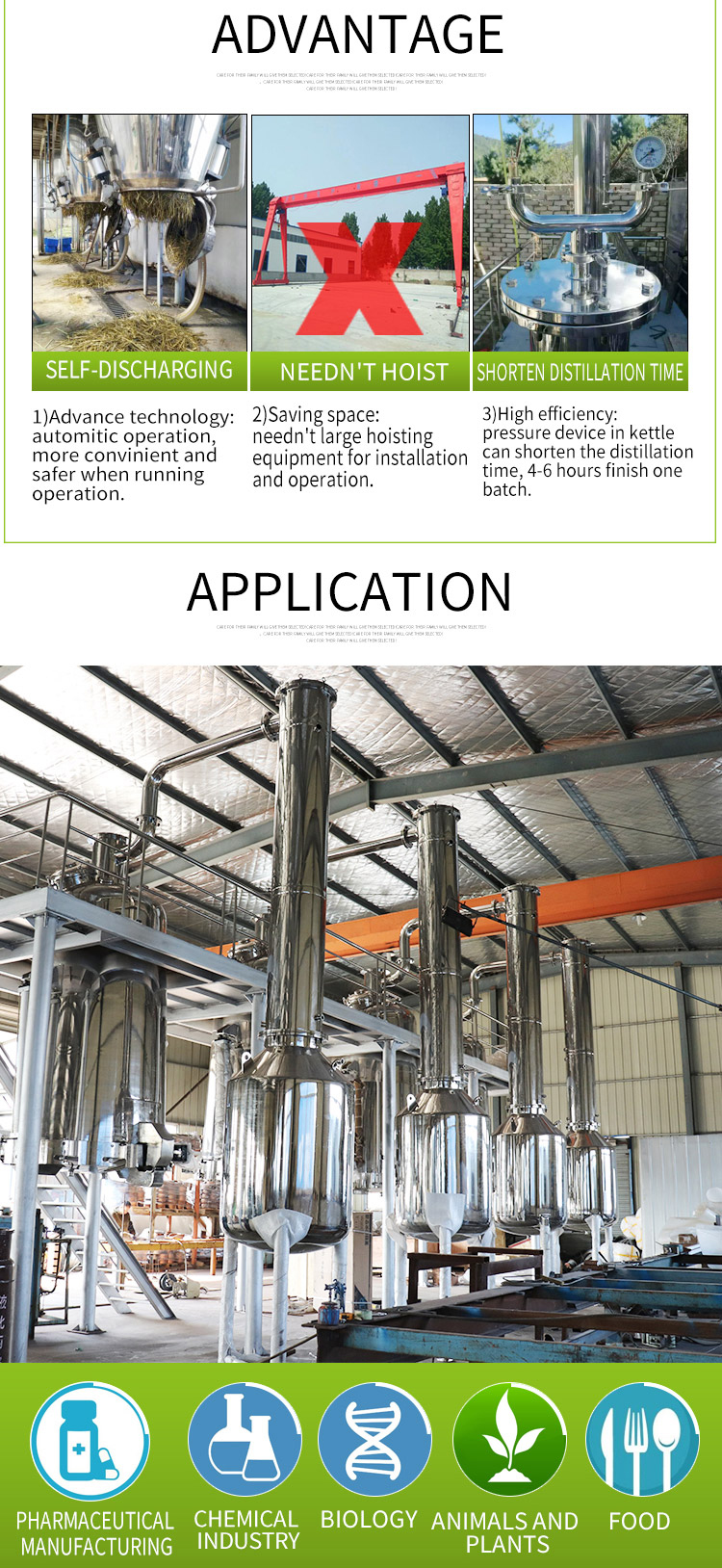

- Advance technology: automatic operation, more convenient and safer when running operation;

- Saving space: needn’t large hoisting equipment for installation and operation;

- High efficiency. Pressure device in the kettle can shorten the distillation time,4-6 hours finish one batch;

- Easy operation. One person can operate this machine easily.

Technical Parameters of 3000l Essential Oil Distillation Equipment

| Distillation kettle | Effective volume: 3000L, using high-pressure steam through heating. |

| Inside: working pressure: normal pressure; | |

| design temperature:120℃,work temperature≤100℃.Working medium:water; Upper oval headδ=5mm/S30408,Cylinder δ=5mm/S30408. |

|

| Discharge slag door:DN1200, Three cylinder rotary slag gate, Single cylinder to open the door, two cylinder locking, a slag door with self-locking cylinder. |

|

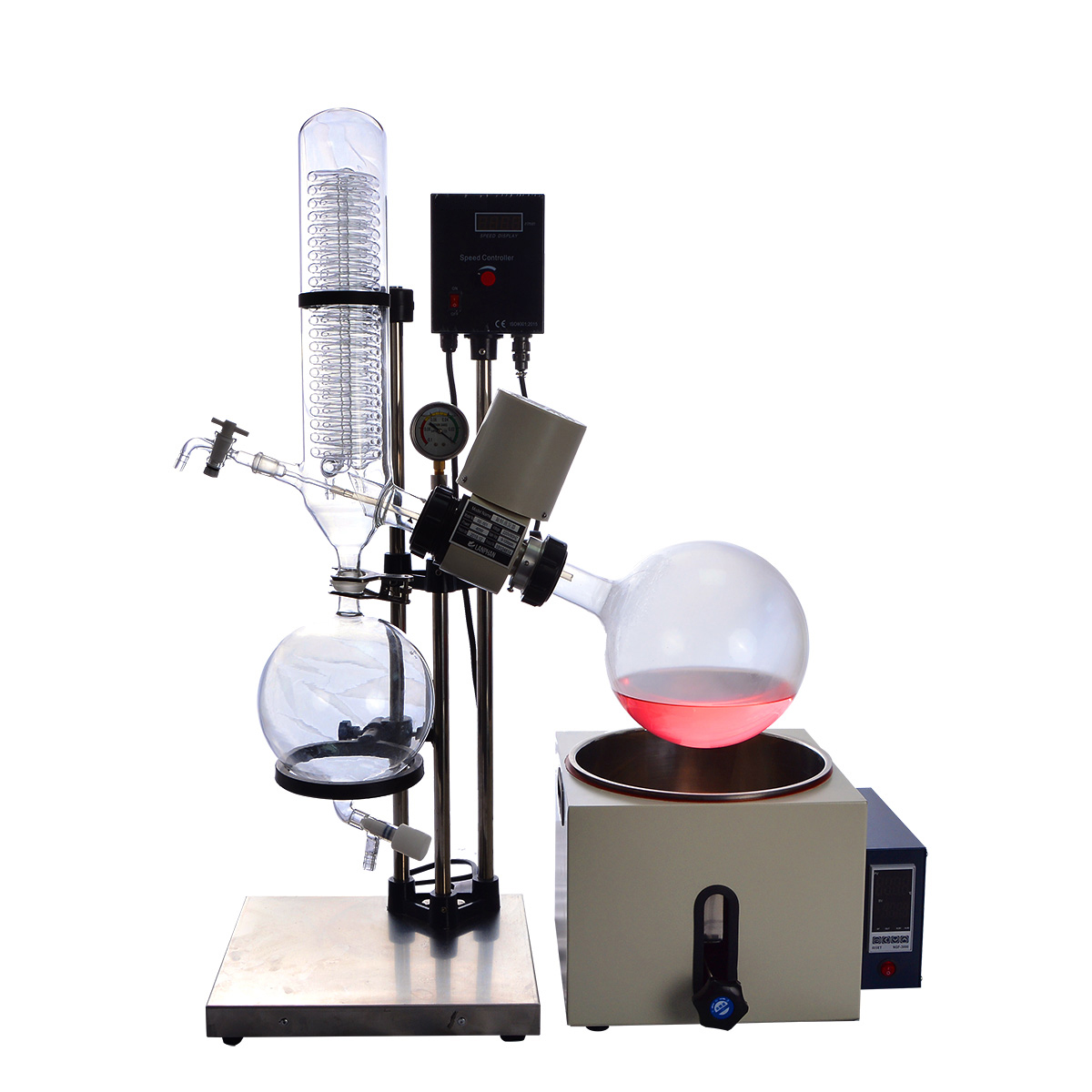

| Demister | Size Φ300×750,δ=3mm/S30408,Demister inside has baffle, The top of the demister is set to the quick opening hole. Demister to facilitate cleaning.Meet the GMP requirements. |

| Condenser | Vertical condenser. |

| Heat transfer area is greater than 10m² . | |

| Pipeline: designed pressure: normal pressure;working pressure: normal pressure | |

| design temperature: 100℃, work temperature≤90℃. | |

| Working medium: Secondary steam. Length: Φ25×2;Material: S30408. | |

| Shell: designed pressure: 0.3Mpa,working pressure: normal pressure; | |

| design temperature: 50℃,work temperature: 15~30℃. | |

| Working medium: cooling water.Size and material:δ=3mm/S30408 | |

| Pure dew collection tank |

material 304 stainless steel,volume 1m³ |

| Oil water separator | Stainless steel tank,Glass as the cup,Dedicated oil – water separator. Volume: 40L,size δ=3mm/S30408 |

| double filter | 120 mesh filter,flow 6.0m³/h,material S30408. |

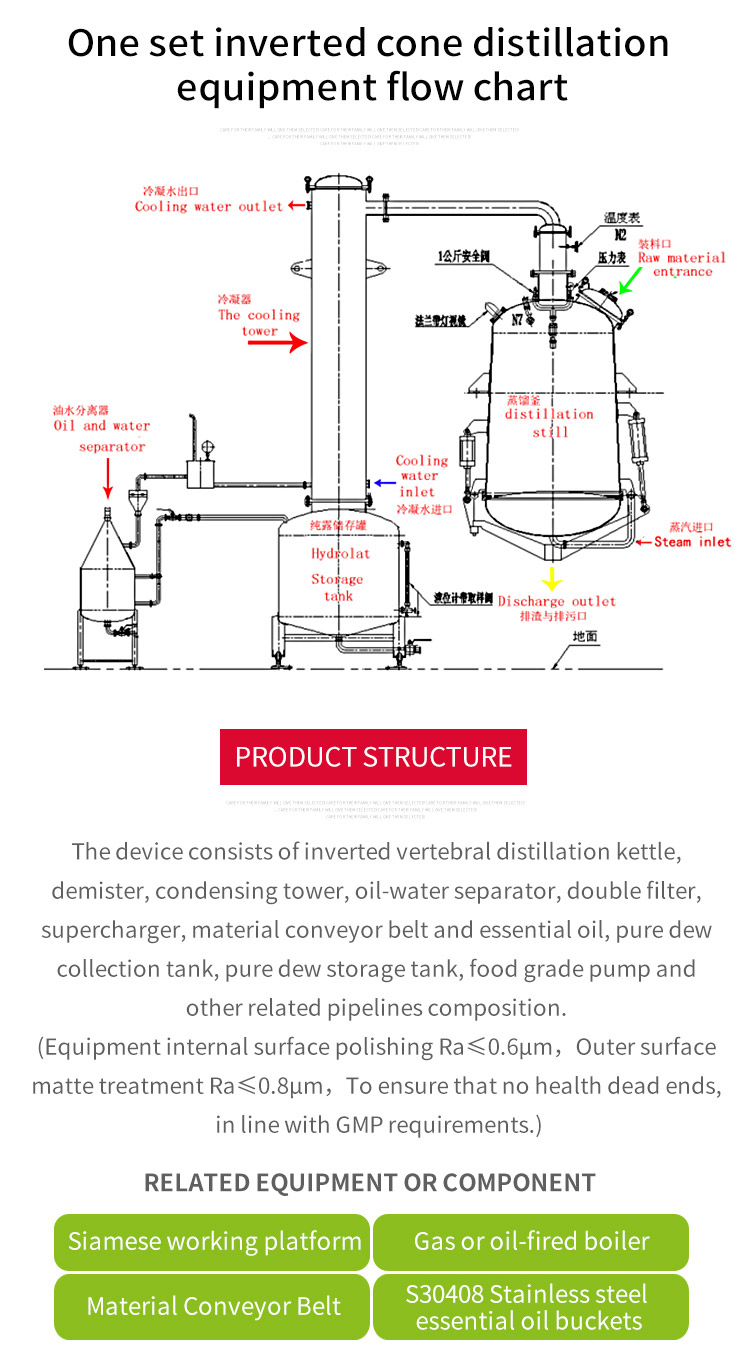

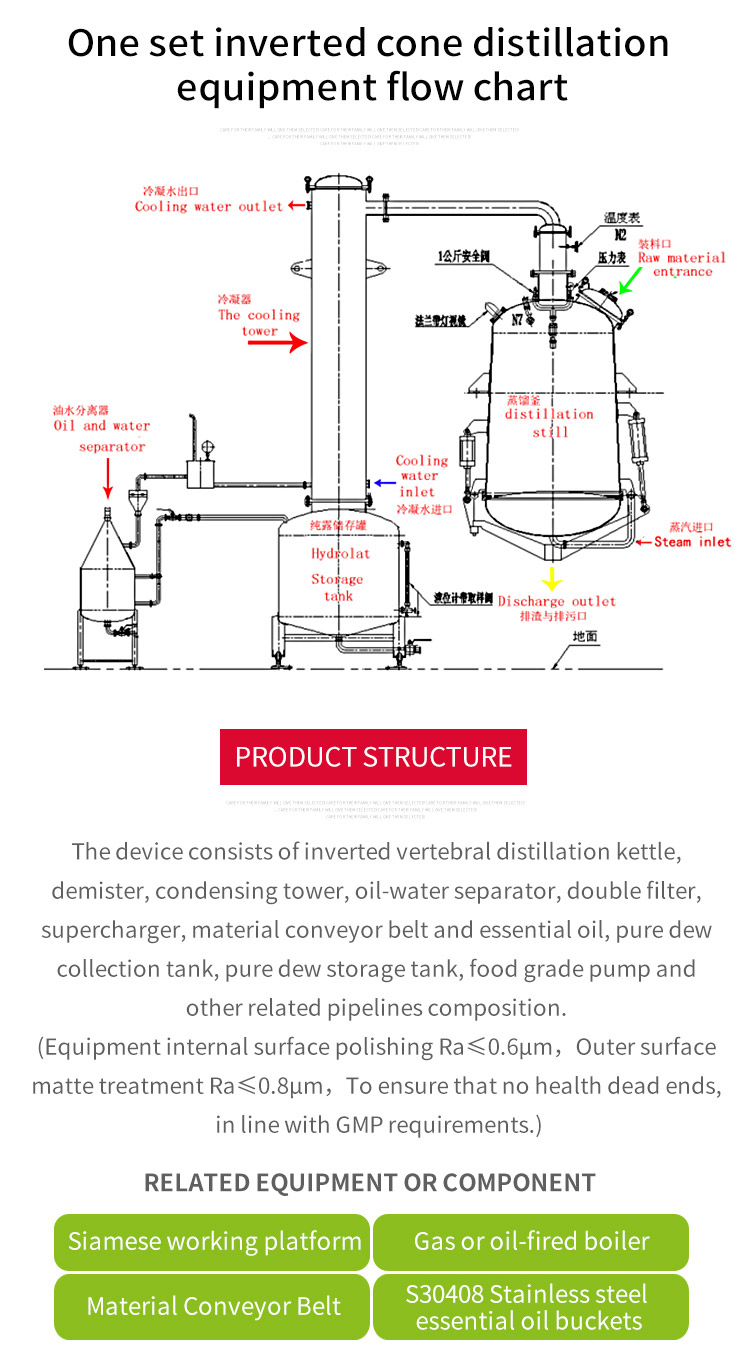

Structure Diagram Of 3000L Essential Oil Distillation Equipment

Structure type: The device consists of inverted vertebral distillation kettle, demister, condensing tower, oil-water separator, double filter, supercharger, material conveyor belt, and essential oil, pure dew collection tank, pure dew storage tank, food-grade pump, and other related pipelines composition. Equipment internal surface polishing Ra≤0.6μm, Outer surface matte treatment Ra≤0.8μm, To ensure that no health dead ends, in line with GMP requirements.

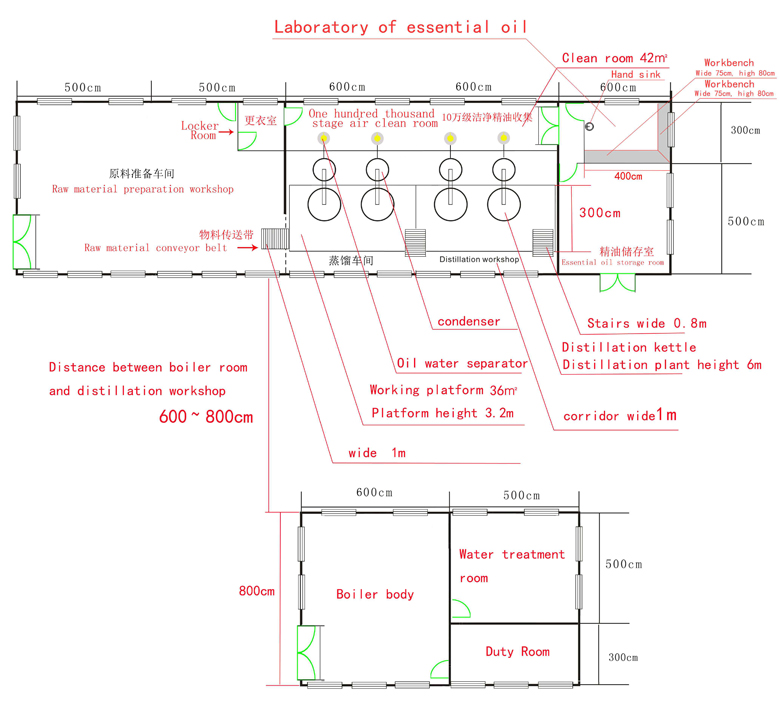

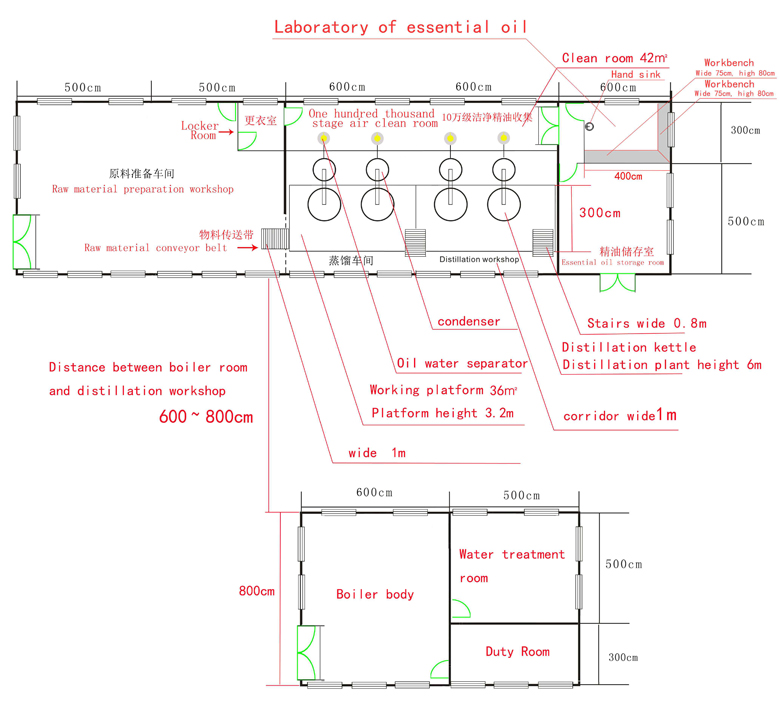

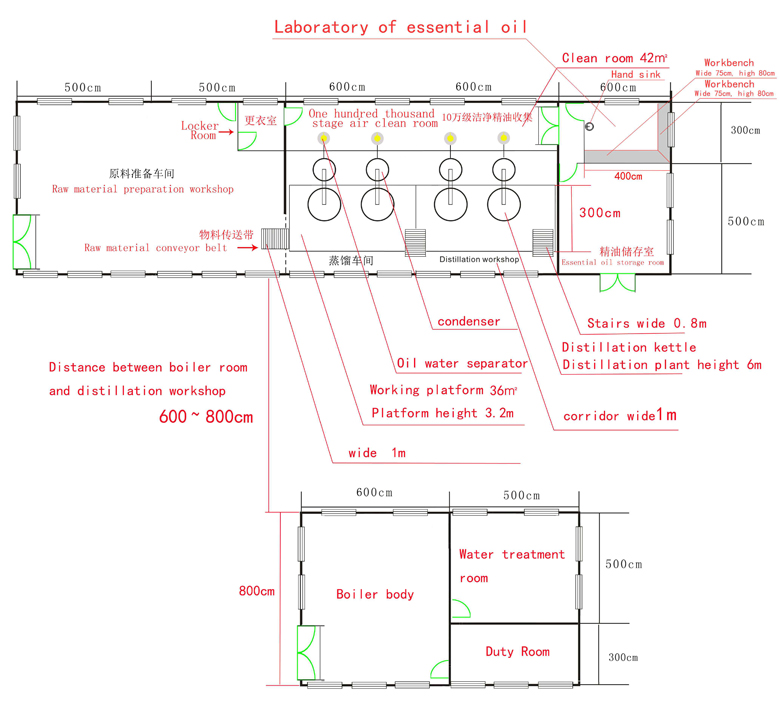

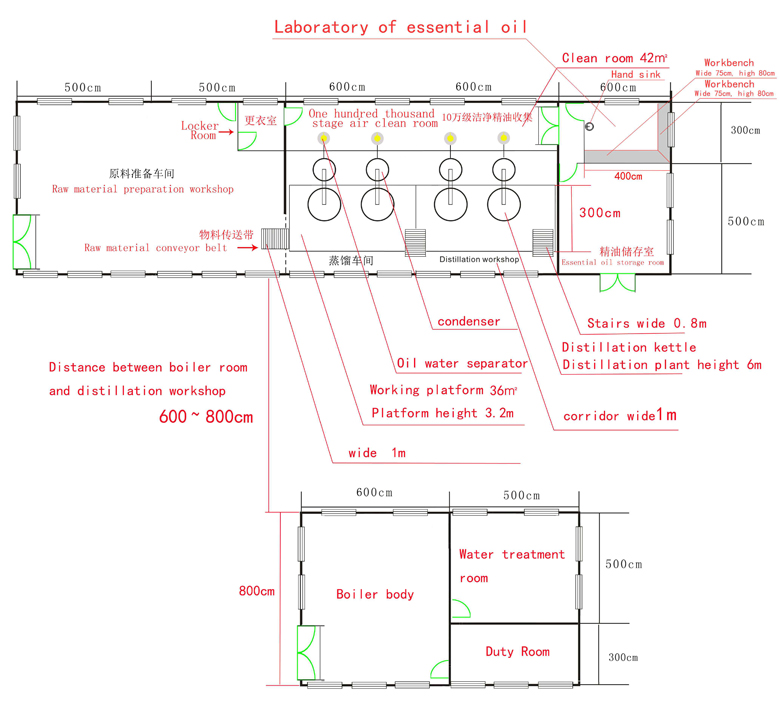

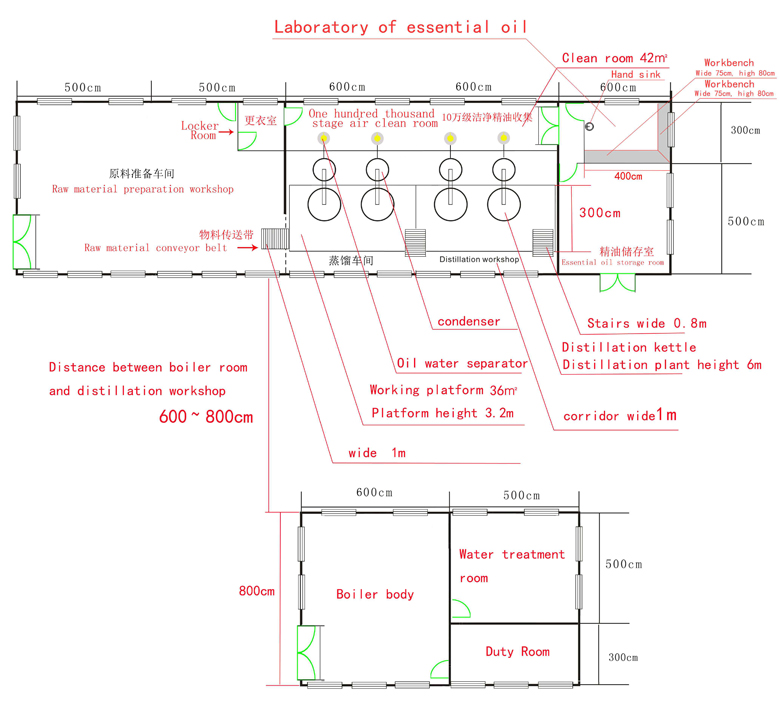

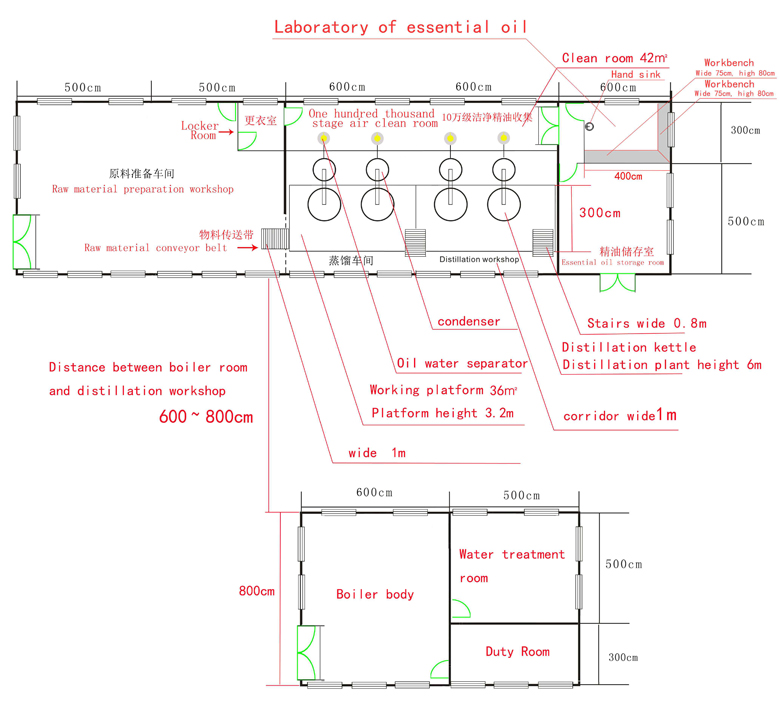

Workshop layout

Application Of Essential Oil Distillation Equipment:

Application

- Essential oil distiller as a common product in producing Chinese traditional medicine is often used to extract effective ingredients from animals and plants and perfume oil in such fields as pharmaceutical manufacturing, biology, food, chemical industry, etc.

- Essential oil distiller is suitable for containing high grease composition of plant leaves, flowers, grass and animal material in conventional oil, essential oil, fragrant oil composition of the water distillation extraction process.

Characters

- Steam distillation: By steam directly -distillation to reach the extraction of essential oils or transfer oil, it can quickly reach 100℃ high.

- High efficiency. Using indirect heating of heat- steam temperature under the conditions of cleanness,

safety, and atmospheric pressure. If required, with the vacuum pump, the extraction speed of essential oils will be faster. - Considerable profit. Once the workshop starts to work there’s considerable profit.

3000l Essential Oil Distillation Extraction Equipment Show

CONTACT US

Send us your enquiries and our representative will answer you accordingly.

Arabic

Arabic Chinese (Simplified)

Chinese (Simplified) Dutch

Dutch English

English French

French German

German Italian

Italian Portuguese

Portuguese Russian

Russian Spanish

Spanish