500l Essential Oil Distillation Extraction Equipment

Product Description

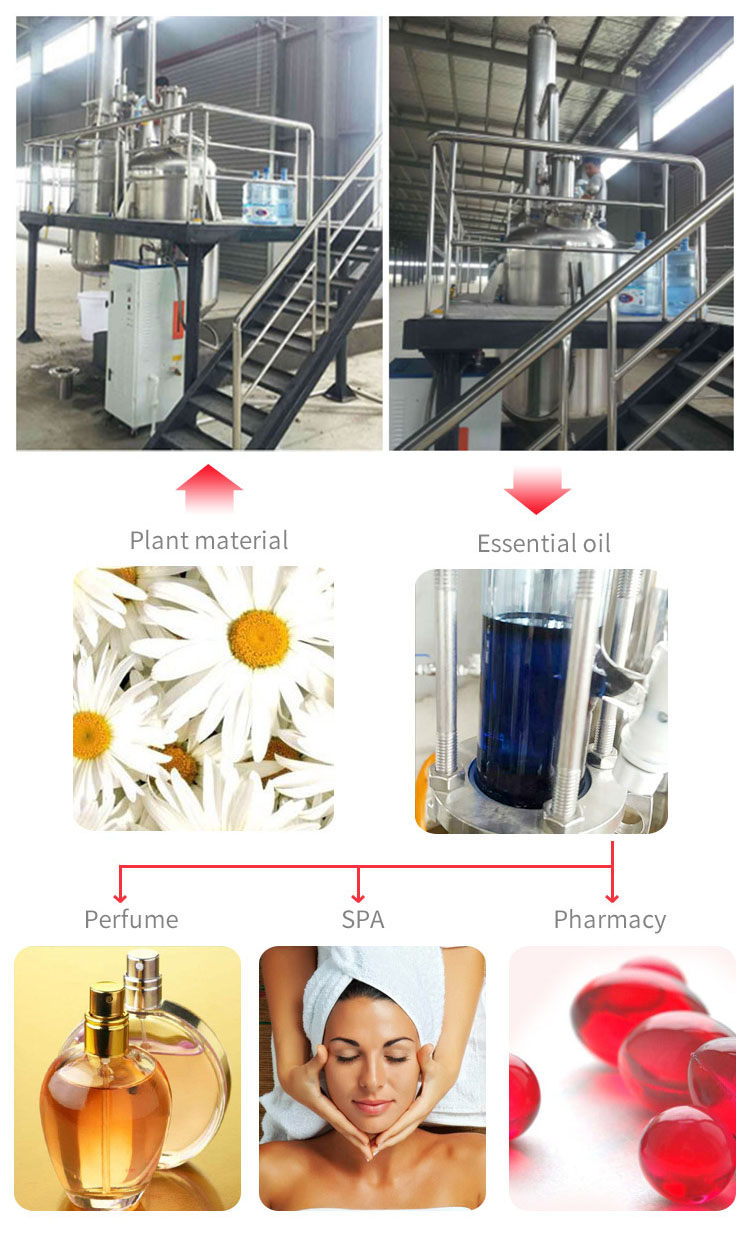

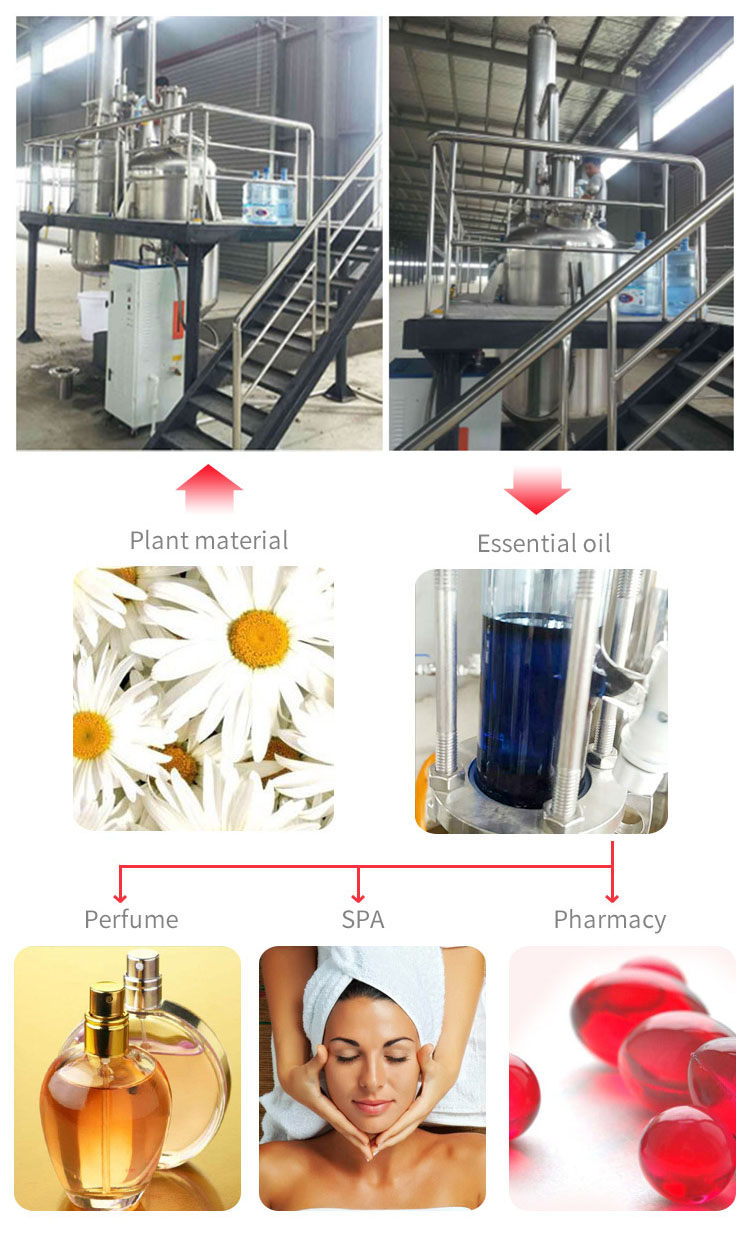

Application of essential oil extraction equipment

- Health products

- Biological drugs

- Cosmetics,Perfumeand food

- Effect of essential oil:

The essence of essential oils can prevent infectious diseases, fight bacteria, viruses, mold, prevent inflammation, prevent spasm, promote cell metabolism, and cell regeneration. - Essential oils for Endocrinology, metabolism, urinary system, venereal, venereal, immune system, gynecologic disease, muscle, bone disease, skin disease, symptoms and diseases of the body, nervous system and mental disease, eye, ear, nose, mouth, dental disease, respiratory system diseases, blood circulation system diseases, Digestive system diseases are very effective.

- In Skincare:

1.Skin whitening

2.Anti-aging

3.shrink pores - Desalination and expulsion of fine lines

- Light spot

In body:

1. Chest and chest

2. Lip Balm

3. Eye Care

Main Advantage Essential oil Extraction Equipment:

- By steam-distillation to reach the extraction of essential oils.

- Easy operation. One people can operate this machine easily.

- High efficiency. Using indirect heating of heat- transfer oil, it can quickly reach 100C high temperature under the conditions of cleanness, safety, and atmospheric pressure. If required, with vacuum pump, the extraction speed of essential oils will be ore faster.

- Compact structure. It covers only about 1.5 square meters.

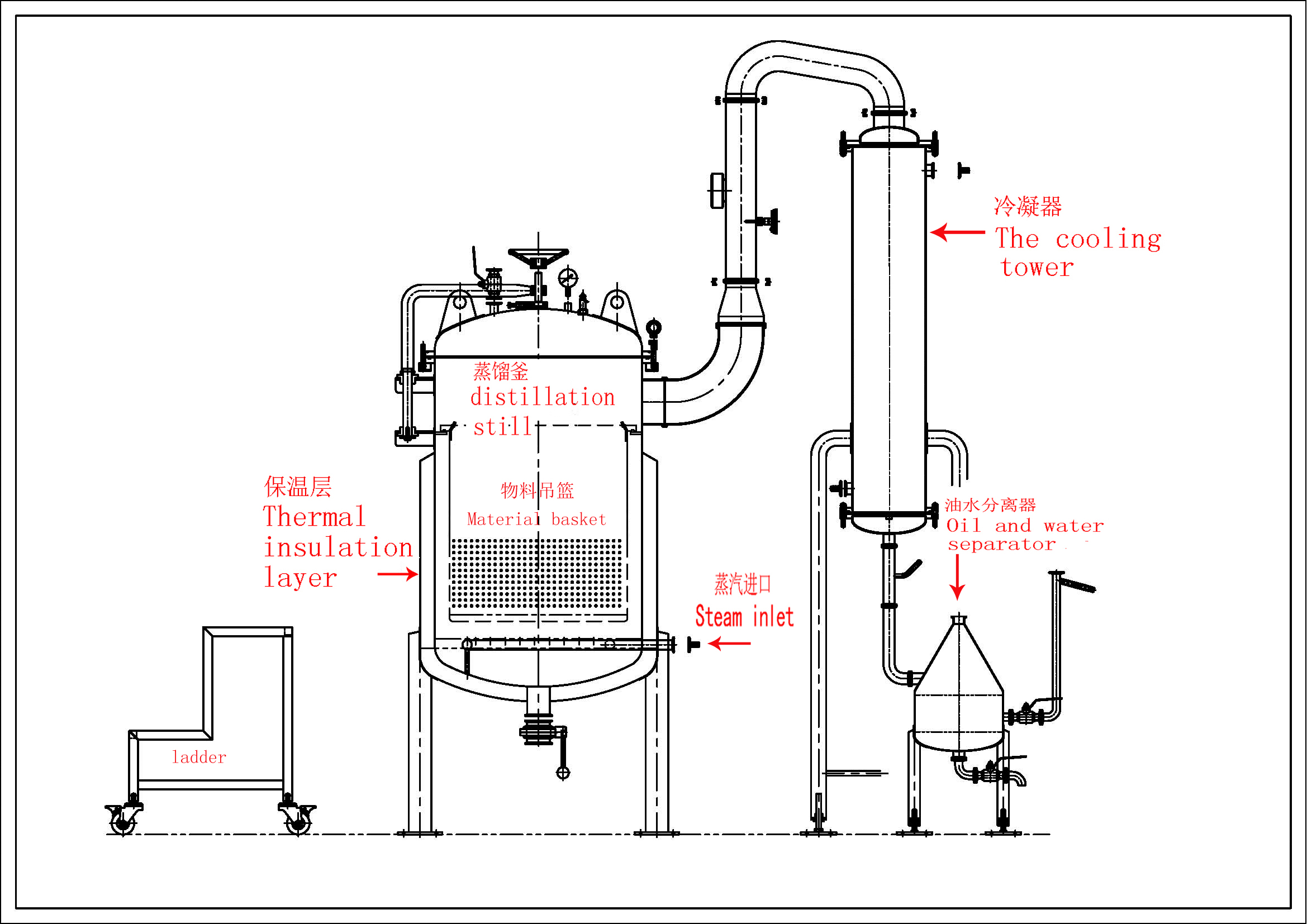

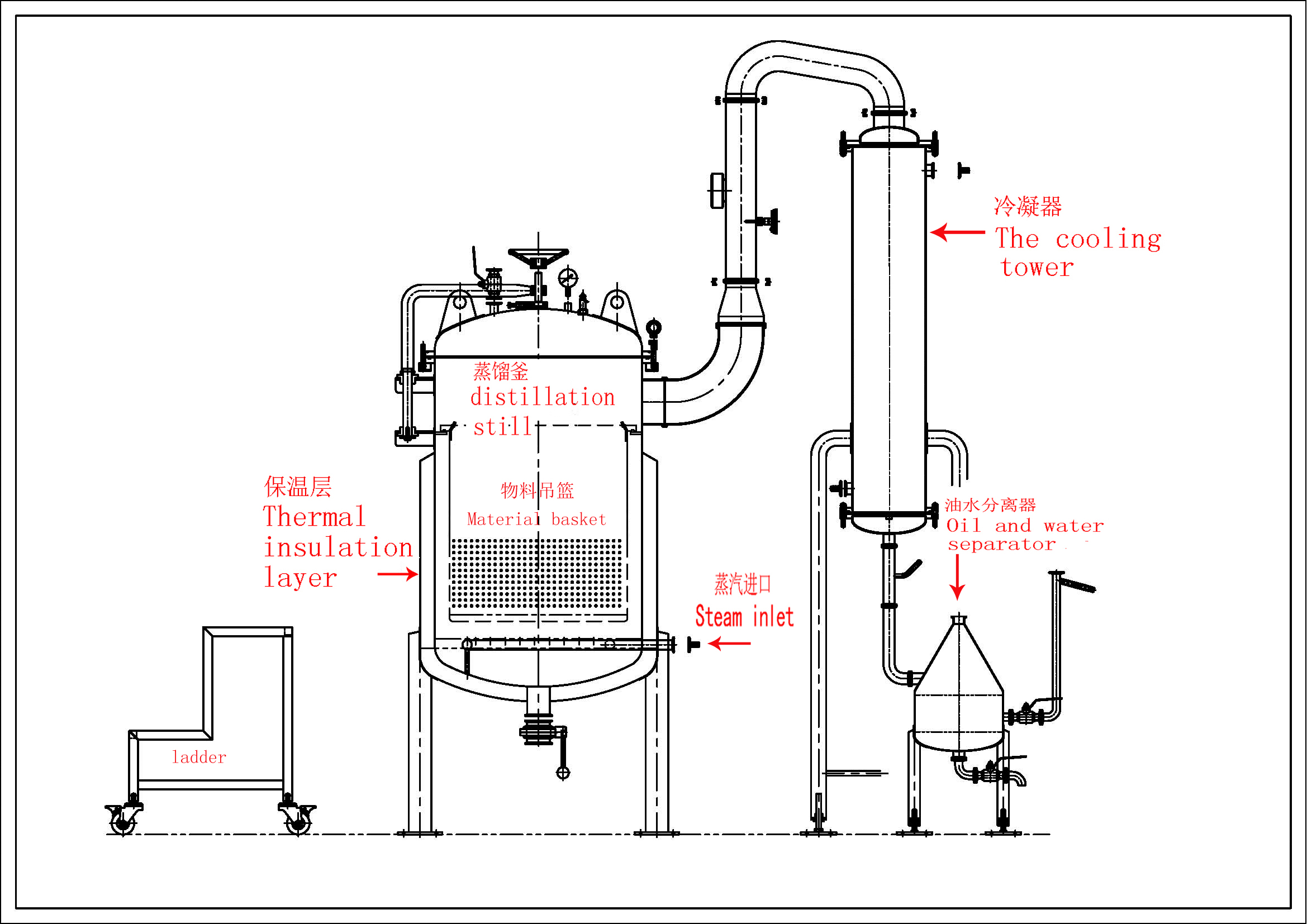

500l Essential Oil Still Structure Diagram

Structure type: The device consists of distillation kettle, material basket, insulation layer, demister, condensing tower, oil-water separator, (Gas or oil-fired boiler), and other related pipeline composition.

Technical Parameters of 500L Essential Oil Distiller

| Distillation still | Actual volume:500L Using steam through heating, heat transfer area of 5m². Kettle: Designed pressure 0.09Mpa. Working pressure: atmospheric Designed temperature:120℃.working temperature≤100℃ Medium: water A slag Outlet: pneumatic slag gate, diameter 1100mm |

| Demister | DimensionΦ200×500,according to GMP |

| Condenser | vertical, heat transfer area more than 2.5 m² Tube pass: Designed pressure:atmospheric Designed temp:100℃, working temp:≤100℃ Medium: Secondary Steam Tube Pass: Φ25×2。 Shell Pass: Designed pressure: 0.3Mpa, working pressure:atmospheric Designed temp.:80℃, working temp:15~30℃ Medium: cooling water |

| Pure Dew storage tank | SS 304 material, volume 450m³ |

| Oil water separator | professional oil-water separator, stainless steel tank, glass, as the cup, the tank volume of 40L . |

| Duplex strainer | 20 mesh filter, flow 2.0m³ / h, material for the S30408. |

| Accessories | A thermometer, a pressure gauge, a mirror. |

| Boiler(gas) | LPG, natural gas, coal gas,liquid gas ,consumption 4.5kg/h. Working voltage:220-240V, Fan power: 120W,Steam temp.:105℃/100℃, working pressure:Low, Steam output:100kg/h Water Pressure :0.12~0.5mpa。 Safety devices: over-temperature, overpressure, water, gas automatic protection |

Material Information of Essential oil distillation extracting equipment

| Flowers | Rose; jasmine; lavender; chamomile; ylang-ylang; geranium; neroli; clary sage; achillea millefolium; osmanthus; peony; marigold; laurel; |

| Leaves | Tea tree; eucalyptus; mint; patchouli; juniper berry; cypress; pine needles; spearmint; basil. |

| Roots | Ginseng; ginger; angelica; garlic; vetivert; angelica root; mugwort; borneol camphor. |

| Grasses | Rosemary; verbena; lemongrass; melissa; nardostachys; tarragon; caraway; dill; valerian; houttuynia; wintergreen; evening primrose. |

| Wood | Sandalwood; cedarwood; rosewood; agarwood; Birch; holly; camphor; melaleuca; sassafras. |

| Resins | Frankincense; myrrh; benzoin; fir tree; Amyris; Elemi. |

| Bark | Cinnamon. |

| Citrus | Bergamot; grapefruit; lemon; orange; lime; tangerine. |

| Seeds | Cloves; almonds; cardamom; carrot seed; pomegranates; pepper; capsicum; fennel. |

Raw Material and Oil Yield:

| Raw material | Oil Yield (%) | Raw material | Oil Yield (%) |

| Gaultheria procumbens | 0.66 | Eugenia caryophylatta | 14-21 |

| Achillea millefolium | 0.007-0.50 | Coriandrumm officinalis | 1 |

| Cymbopogon nardus | 2.0-4.0 | Anetlnun graveolens | 2.5-4 |

| Pimenta d ica | 4.5 | Eucalyprus spp | 1.0-7.0 |

| Angelica seed | 0.3-1.0 | Foeniculum vulgare | 4 .0-6.0 |

| Angelica plant | 0.6-1.5 | Boswellia carterii | 3.5-6.0 |

| Amica montana plant | 1 | Pelargonium graveolens | 0.3-2.0 |

| Amica montana flower | 1 | Juniperus communis | 1.5 |

| arusum | 1.5-4 | Lavendula angustifolia | 0.5-1.0 |

| Ocimum basilicum | 0.5-1.5 | Citrus limonum | 2 |

| Laurel nobilus | 3 | Melissa offivinalis | 0.015 |

| Melaleuca leucadendron | 1 | Origarunn majorana | 0.9 |

| Cinnamomum camphora | 2 | Myristica fragrans | 15-25 |

| Carum carvi | 3.2-7.4 | Citrus spp | 1.5-2.0 |

| Cinnamomum cassia | 1.5 | Origanum vulgare | 1.2 |

| Santalum album | 2-4.5 | Petroselinum crispum | 6 |

| Matricaria chamomilla | 0.3-1 | Mentha piperita | 1.0-2.5 |

| Anthemis nobilis | 0.3-1 | Pinus spp | 0.5-3.0 |

| Cinnamomum zeylanicum | 0.1 | Rosa spp | 0.04 |

| Salvia sclarea | 0.1-0.34 | Rosmarinus officinalis | 0.5-2.0 |

CONTACT US

Send us your enquiries and our representative will answer you accordingly.