800l Essential Oil Distillation Extraction Equipment

Introduction of 800L Essential Oil Distiller

Our essential oil extraction equipment is popular in production of health products, biological drugs, cosmetics, and food. This uses technology and chemical separation,can extract plant components efficiently by steam distillation, have good effect in collecting essential oil from plants.

Part List of essential distiller:

- Extracting tank

- Oil-water separator

- Receiver

- Oil cooling system

- Plate distillation system

- Vacuum system

- Frame

- Pipes

- Valves

- Digital temperature sensor.

Main Advantage of 800L Essential Oil Distiller

- By steam-distillation to reach the extraction of essential oils.

- Easy operation. One person can operate this machine easily .

- High efficiency. Using indirect heating of heat- transfer oil, it can quickly reach 100℃ high temperature under the conditions of cleanness, safety, and atmospheric pressure. If required, with vacuum pump, the extraction speed of essential oils will be ore faster.

- Made with 304 Stainless steel with the density absolutely free from the erosion of essential oil.

- Environmentally friendly. no smoke, no odor, without secondary pollution, the whole process is all sealed, won’t release any gas harmful to human and environment.

Technical Parameters of 800L Essential Oil Distiller

| Distillation kettle | Effective volume: 800L, using high-pressure steam through heating.

Inside: working pressure: normal pressure;design temperature:120℃,work temperature≤100℃.Working medium:water; Upper oval headδ=5mm/S30408,Cylinder δ=5mm/S30408. Discharge slag door:DN1200, Three-cylinder rotary slag gate, Single cylinder to open the door, two-cylinder locking, a slag door with the self-locking cylinder. |

| Demister | Size Φ300×750,δ=3mm/S30408,Demister inside has baffle, The top of the demister is set to the quick opening hole. Demister to facilitate cleaning. Meet the GMP requirements. |

| Condenser | Vertical condenser. Heat transfer area is greater than10m2.

Pipeline:designed pressure: normal pressure;working pressure: normal pressure;design temperature:100℃, work temperature≤90℃. Working medium: Secondary steam. Length:Φ25×2,Material: S30408。 Shell:designed pressure: 0.3Mpa,working pressure: normal pressure;design temperature:50℃,work temperature:15~30℃. Working medium:cooling water. Size and material:δ=3mm/S30408 |

| Pure dew collection tank | material 304 stainless steel,volume 1m³ |

| Oil-water separator | Stainless steel tank,Glass as the cup,Dedicated oil-water separator. Volume: 40L,size δ=3mm/S30408 |

| double filter | 120 mesh filter,flow 6.0m3/h,material S30408。 |

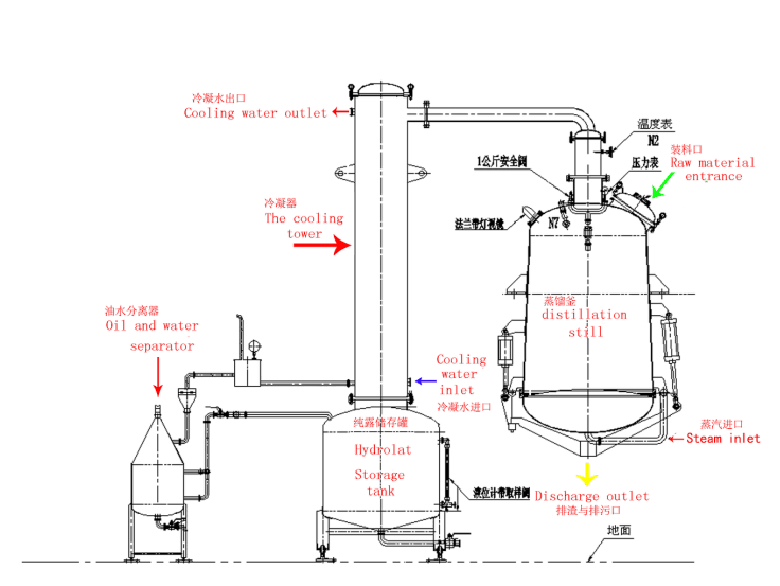

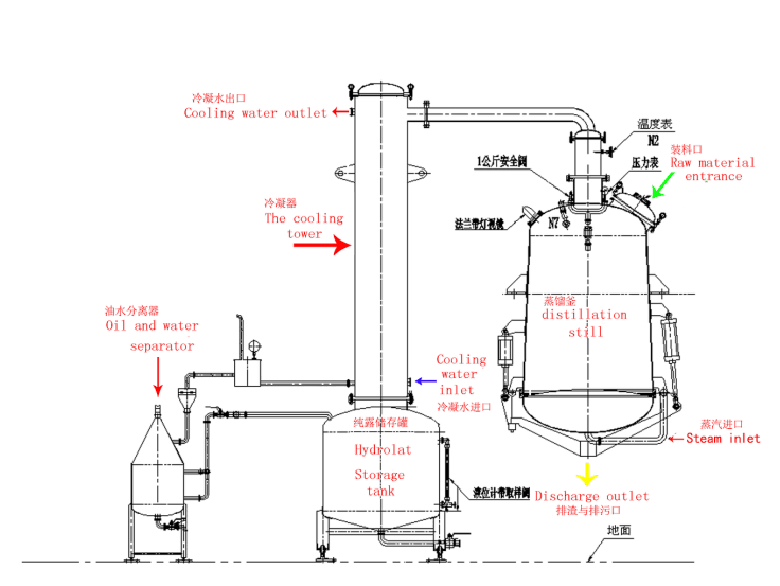

800l Essential Oil Still Structure Diagram

One set inverted cone distillation equipment flow chart

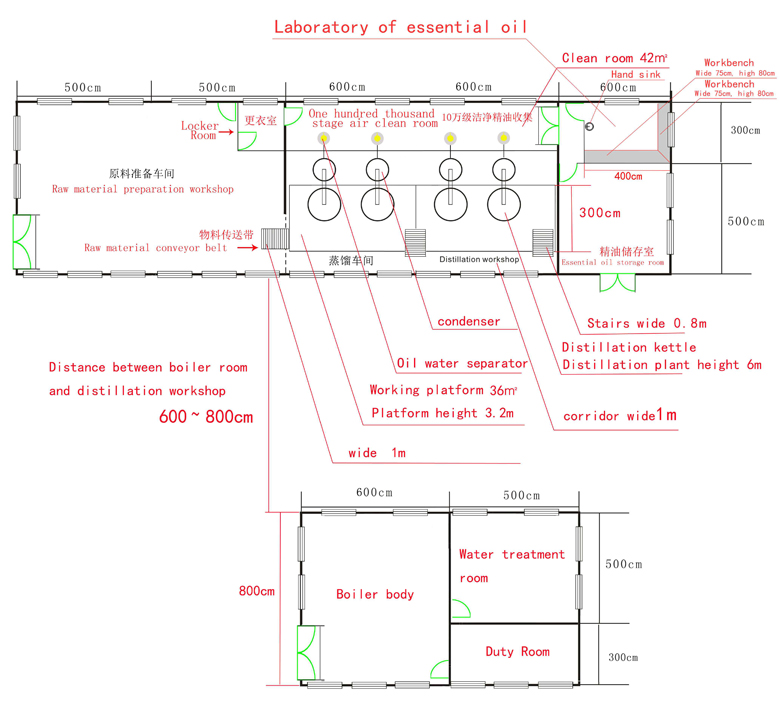

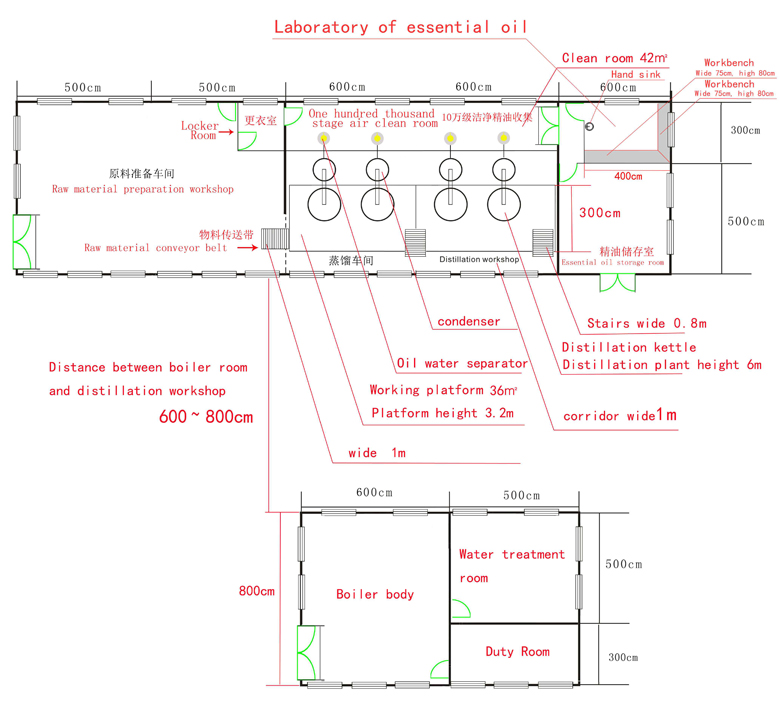

Workshop layout

Material of 800l Essential Oil Distiller

| Raw material | Use the parts | Raw material | Use the parts |

| Gaultheria procumbens | leaf | Cinnamomum cassia | Cinnamon bark |

| Achillea millefolium | Flowers, upper branches | Santalum album | Wood core,root core |

| Cymbopogon nardus | Leaf blade | Matricaria chamomilla | flowers |

| Pimenta dioica | seeds | Anthemis nobilis | flowers |

| Angelica archengelica | root | Cinnamomum zeylanicum | Wood core,root core |

| Angelica archengelica | seeds | Salvia sclarea | Leaf ,upper branch |

| Pimpinella anisum | seeds | Eugenia caryophylatta | bud |

| Arnica montana | root | Eugenia caryophylatta | Leaf |

| Melaleuca leucadendron | Leaves and twigs | Eucalyptus spp | Leaves and twigs |

| Cinnamomum camphora | Leaves and twigs | Foeniculum vulgare | seeds |

| Carum carvi | seeds | Boswellia carterii | Resin adhesive |

| Myristica fragrans | seeds | Citrus spp | pericarp |

| Citrus spp | Flowers | Origanum vulgare | Leaf ,upper branch |

| Petroselinum crispum | seeds | Petroselinum crispum | Leaf ,upper branch |

| Mentha piperita | Leaf | Pinus spp | needle |

| Rosa spp | Flowers | Rosmarinus officinalis | Leaf |

Detail Show

CONTACT US

Send us your enquiries and our representative will answer you accordingly.